Mitsubishi Outlander: Differential

DISASSEMBLY AND ASSEMBLY

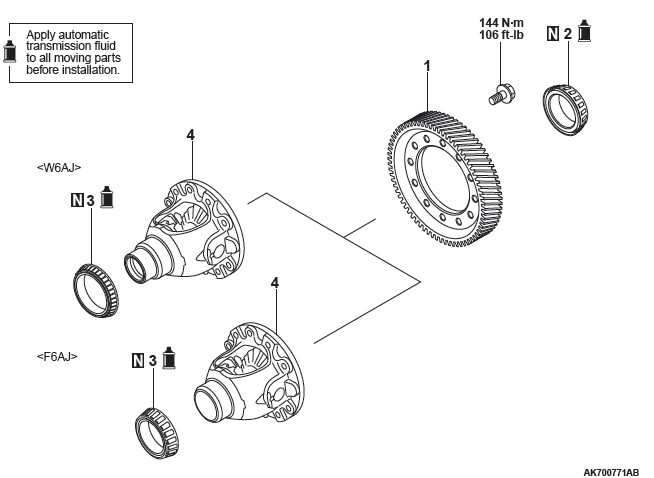

Disassembly Steps

- Final gear

- Differential side bearing (transmission case side)

- Differential side bearing (converter housing side)

- Differential sub-assembly

Required special tools:

- MB990801: Real axle bearing puller

- MB990811: Side bearing puller cap

- MB990956: Needle bearing installer

- MB990810: Side bearing puller

- MD999566: Claw

- MD998761: Cam oil seal installer

- MD998812: Installer cap

- MD998813: Installer-100

- MD998826: Installer adapter

- MB991559: Cam oil seal installer adapter

- MB992213: Bearing installer

- MB992150: Oil seal installer

DISASSEMBLY SERVICE POINT

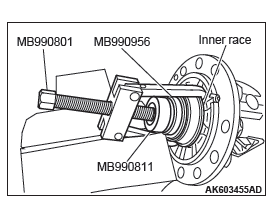

DIFFERENTIAL SIDE BEARING REMOVAL

1. Break and remove the roller of the differential side bearing.

2. Using the special tools MB990801, MB990811 and MB990956, remove the inner race of differential side bearing (transmission case side) from the differential sub-assembly.

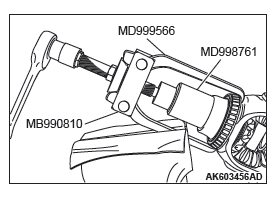

DIFFERENTIAL SIDE BEARING REMOVAL

1. Using the special tools MB990810, MD999566 and MD998761, remove the inner race of differential side bearing (converter housing side) from the differential sub-assembly.

ASSEMBLY SERVICE POINT

DIFFERENTIAL SIDE BEARING INSTALLATION

CAUTION

- Do not re-use the inner race.

- Replace the inner race together with the outer race.

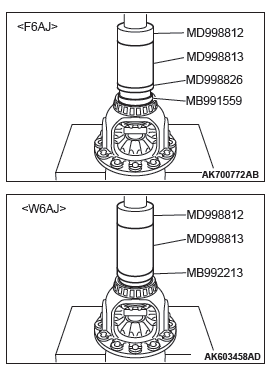

Using the special tools MD998812, MD998813, MD998826 <F6AJ> and MB991559 <F6AJ> or MB992213 <W6AJ>, install the differential side bearing (converter housing side) on the differential sub-assembly.

DIFFERENTIAL SIDE BEARING INSTALLATION

CAUTION

- Do not re-use the inner race.

- Replace the inner race together with the outer race.

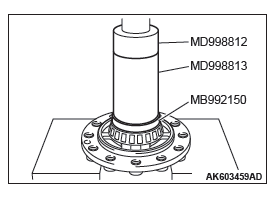

Using the special tools MD998812, MD998813 and MB992150, install the inner race of differential side bearing (transmission case side) on the differential sub-assembly.

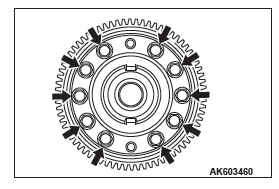

FINAL GEAR INSTALLTION

CAUTION

- The differential sub-assembly can be only assembled, but not disassembled.

- Assemble the final gear to the differential assembly in the chamfer direction in the inside diameter of the final gear.

- Tighten bolts diagonally.

Install the final gear on the differential assembly. Refer to the following or the exploded view for the tightening torque.

Tightening torque: 144 N*m (106 ft-lb)