Mitsubishi Outlander: Differential

DISASSEMBLY AND ASSEMBLY

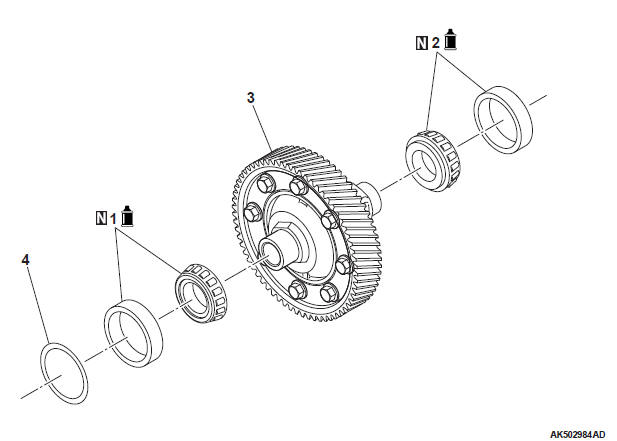

Disassembly steps

- Differential side bearing

- Differential side bearing

- Differential sub-assembly

- Adjusting shim

Required special tools:

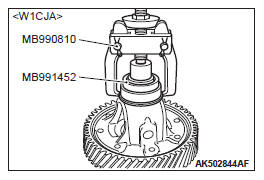

- MB990810: Side bearing puller

- MB991452: Oil seal installer

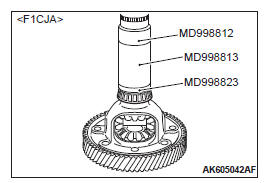

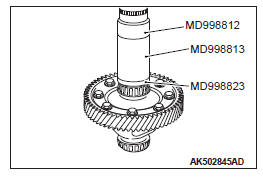

- MD998812: Installer cap

- MD998813: Installer-100

- MD998823: Installer adapter (48)

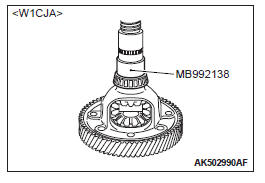

- MB992138: Bearing Installer

DISASSEMBLY SERVICE POINT

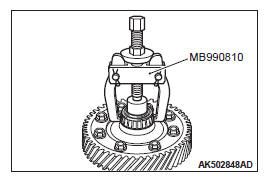

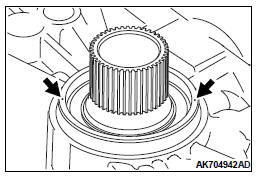

DIFFERENTIAL SIDE BEARING REMOVAL

Using the special tool MB990810, remove the inner race of differential side bearing (transaxle case side) from the differential sub-assembly.

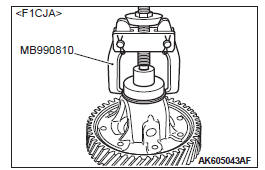

DIFFERENTIAL SIDE BEARING REMOVAL

Using the special tools MB990810 and MB991452 <W1CJA>, remove the inner race of differential side bearing (converter housing side) from the differential sub-assembly.

REASSEMBLY SERVICE POINT

DIFFERENTIAL SIDE BEARING INSTALLATION

CAUTION

- Do not re-use the inner race.

- Replace the inner race together with the outer race.

Using the special tool MD998812,MD998813 and MD998823 <F1CJA> or MB992138 <W1CJA>, install the inner race of reduction gear bearing (converter housing side) on the reduction gear sub-assembly.

REDUCTION GEAR BEARING INSTALLATION

CAUTION

- Do not re-use the inner race.

- Replace the inner race together with the outer race.

Using the special tools MD998812, MD998813 and MD998823, install the inner race of reduction gear bearing (transaxle case side) on the reduction gear sub-assembly.

Differential Sub-assembly

DIFFERENTIAL SUB-ASSEMBLY

Measure the inner race press-fit shaft diameter of differential sub-assembly, and replace the assembly if the diameter does not meet the standard value.

Standard values

- Converter housing side <F1CJA>

φ40.026 − 40.051 mm (φ1.5758 − 1.5768 in) - Converter housing side <W1CJA>

φ60.032 − 60.078 mm (φ2.3635 − 2.3653 in) - Transaxle case side

φ40.026 − 40.051 mm (φ1.5758 − 1.5768 in)

DIFFERENTIAL SUB-ASSEMBLY

ASSEMBLY

CAUTION The differential sub-assembly can only be assembled, not disassembled.

Assembly steps

- Differential case

- Final gear

ASSEMBLY SERVICE POINT

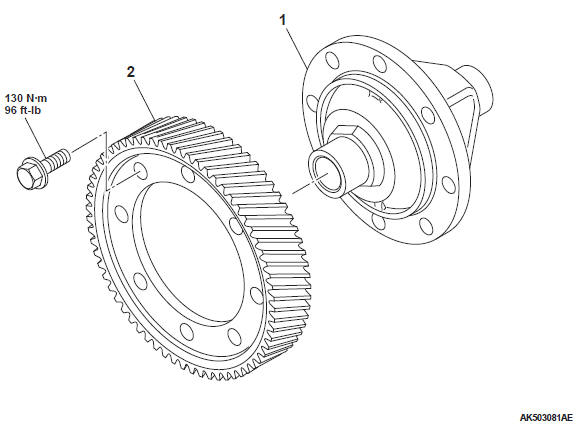

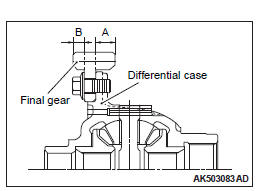

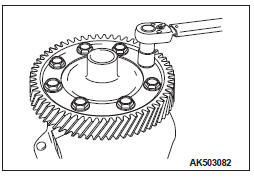

DIFFERNTIAL CASE / FINAL GEAR INSTALLATION

CAUTION When attaching the final gear to the differential case, make sure the side with the bigger distance from the edge to the flange A face the differential case.

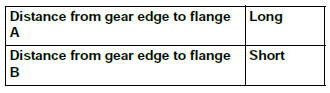

Install the final gear on the differential case, and tighten the fastening bolts to the specified torque.

Tightening torque: 130 N*m (96 ft-lb)

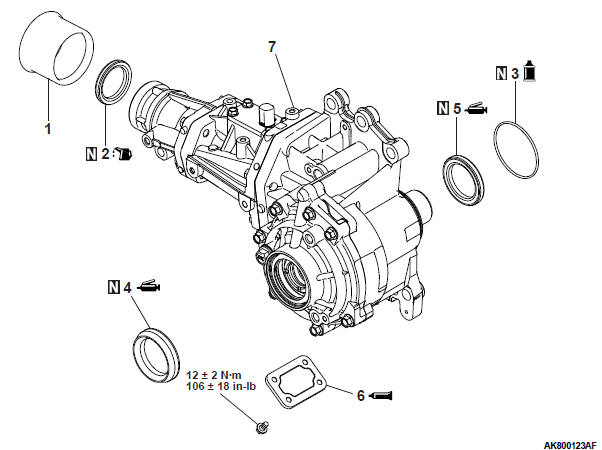

Transfer

DISASSEMBLY AND ASSEMBLY

Disassembly steps

- Dust seal guard

- Oil seal

- O-ring

- Oil seal

- Oil seal

- Cover

- Transfer

Required special tools:

- MD998812: Installer cap

- MB992154: Oil seal installer

- MB992075: Handle

- MB992142: Oil seal installer

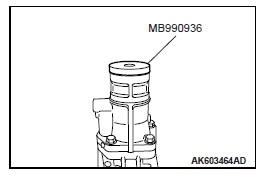

- MB990936: Installer adapter

ASSEMBLY SERVICE POINT

COVER INSTALLATION

1. Apply a 1.5 mm diameter bead of sealant as illustrated onto the cover.

3M ATD Part No.8660 or equivalent

2. Attach the cover to the transfer and tighten it to the specified torque.

Tightening torque: 12 +- 2 N*m (106 +- 18 in-lb)

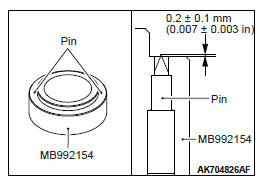

OIL SEAL INSTALLATION

CAUTION Pay attention to the transfer case that can possibly twist when the pin projection is too large.

1. Adjust the projection allowances of the two pins of the special tool, Oil Seal Installer (MB992154) to be 0.2 +- 0.1 mm (0.007 +- 0.003 in).

NOTE: The two pins are inserted into the special tool, Oil Seal Installer (MB992154). When the oil seal is replaced, the traces are found on the transfer case so that the replacement using the specified special tool can be recognized.

2. Apply specified grease to the oil seal lip area.

Specified grease: Retinax A

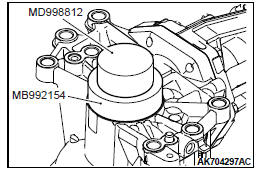

3. Using the special tool MD998812 and MB992154, install the oil seal.

4. Check whether the two traces are found on the transfer case.

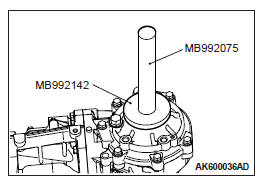

OIL SEAL INSTALLATION

1. Using the special tool MB992075 and MB992142, install the oil seal.

2. Apply specified grease to the oil seal lip area.

Specified grease: Retinax A

OIL SEAL INSTALLATION

1. Using the special tool MB990936, install the oil seal.

2. Apply transfer oil to the lip of oil seal.