Mitsubishi Outlander: Power Steering Oil Pump Assembly

REMOVAL AND INSTALLATION

Pre-removal operation

- Power Steering Fluid Draining

- Engine Upper Cover Removal

- Engine Room Side Cover (RH) Removal

- Generator and Others Belt Removal

Post-installation operation

- Generator and Others Belt Installation

- Generator and Others Belt Tension Check

- Engine Upper Cover Installation

- Engine Room Side Cover (RH) Installation

- Power Steering Fluid Refilling and Bleeding

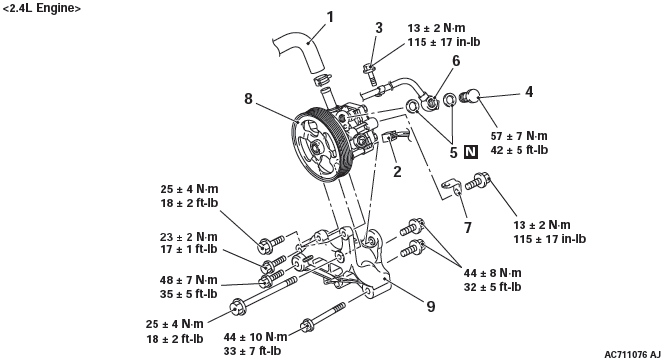

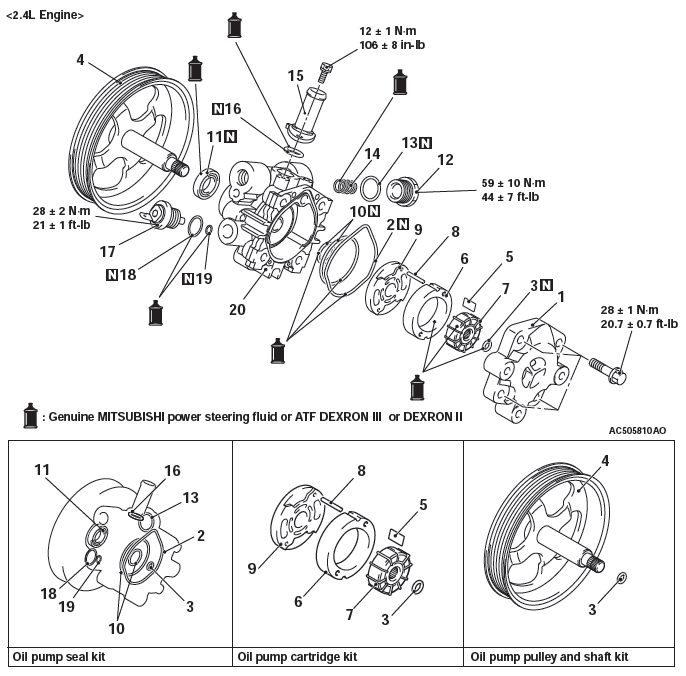

<2.4L Engine>

Removal steps

- Suction hose connection

- Pressure switch connector connection

- Clamp bolt

- Eye bolt

- Gasket

- Pressure hose assembly connection

- Harness bracket

- Oil pump assembly

- Oil pump bracket

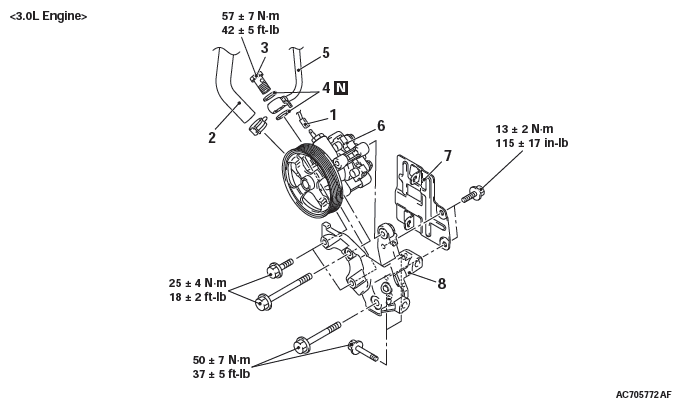

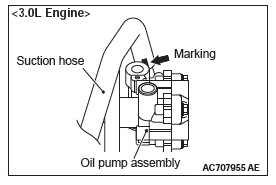

<3.0L Engine>

Removal steps

- Pressure switch connector connection

- Suction hose connection

- Eye bolt

- Gasket

- Pressure hose assembly connection

- Oil pump assembly

- Heat protector

- Power steering pump bracket

REMOVAL SERVICE POINT

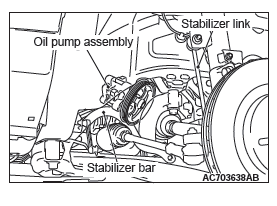

OIL PUMP ASSEMBLY REMOVAL

When removing the oil pump assembly, remove the stabilizer link and stabilizer bar bracket, shift the stabilizer bar to the left of the vehicle, and then remove the assembly from the front wheel house (right side).

INSTALLATION SERVICE POINT

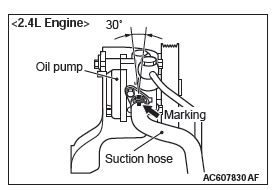

SUCTION HOSE CONNECTION

Align the suction hose marking within the area shown in the figure and connect the suction hose.

INSPECTION

- Check the drive belt for cracks.

- Check the pulley for uneven rotation.

DISASSEMBLY AND ASSEMBLY

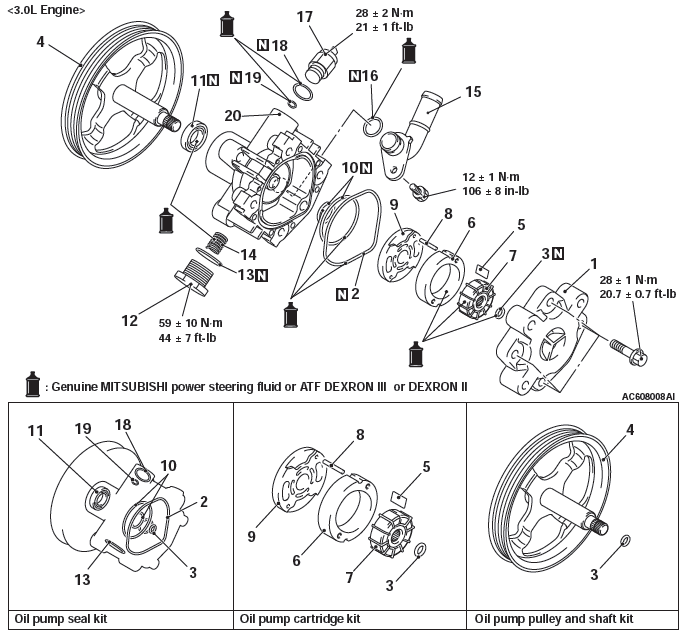

CAUTION Do not use ATF-SP II M and ATF-SP III for the power steering fluid.

<2.4L Engine>

<3.0L Engine>

Disassembly steps

- Pump cover

- O-ring

- Snap ring

- Pulley and shaft

- Vane

- Cam ring

- Rotor

- Pin

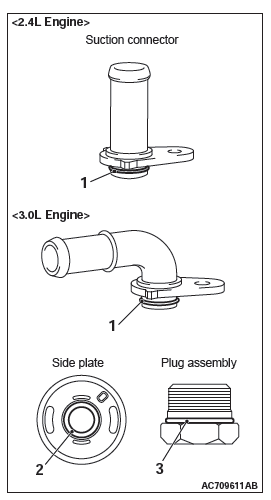

- Side plate

- O-ring

- Oil seal

- Plug assembly

- O-ring

- Flow control spring

- Suction connector

- O-ring

- Terminal assembly

- O-ring

- O-ring

- Oil pump case

Required Special Tools:

- MB990938: Bar (Snap-in type)

- MB991203: Oil Seal and Bearing Installer

ASSEMBLY SERVICE POINTS

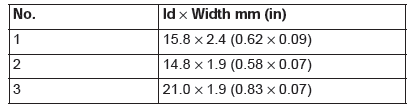

O-RING INSTALLATION

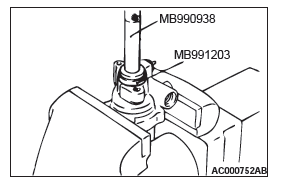

OIL SEAL INSTALLATION

Use the following special tools to install the oil seal.

- Installer special tool bar (MB990938) [Including in the special tool bearing and oil seal installer set (MB990925) ]

- Special tool oil seal and bearing installer (MB991203)

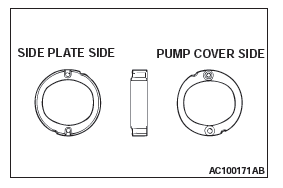

CAM RING INSTALLATION

CAUTION Be sure to install the cam ring in the correct direction as shown.

Install the cam ring as shown in the illustration.

INSPECTION

- Check the pulley and shaft for wear or damage.

- Check the rotor and vane groove for "stepped" wear.

- Check the contact surface of cam ring and vanes for "stepped" wear.

- Check the vanes for damage.