Mitsubishi Outlander: Reduction Gear

DISASSEMBLY AND ASSEMBLY

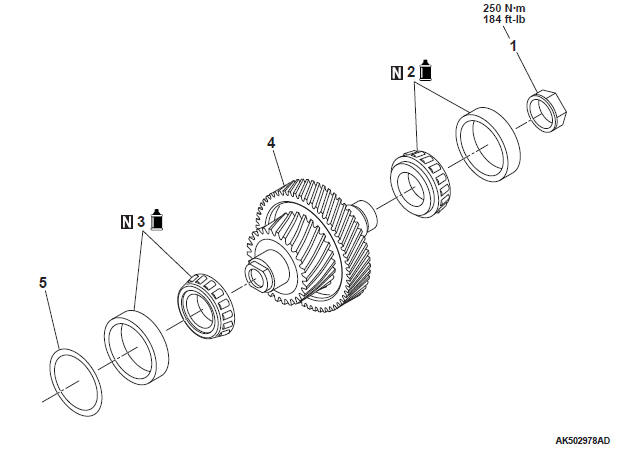

- Nut

- Reduction gear bearing

- Reduction gear bearing

- Reduction gear sub-assembly

- Adjusting shim

Required special tools:

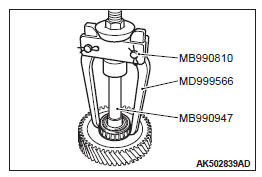

- MB990810: Side bearing puller

- MB990947: Lower arm push arbor

- MD999566: Crow

- MB990984: Mount bushing lower roll insulator arbor

- MD998917: Bearing remover

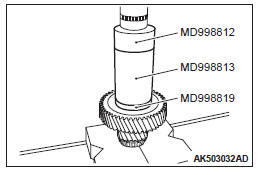

- MD998812: Installer Cap

- MD998813: Installer-100

- MD998819: Installer adapter (40)

DISASSEMBLY SERVICE POINT

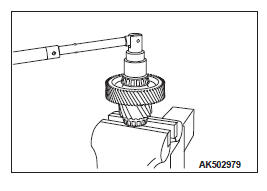

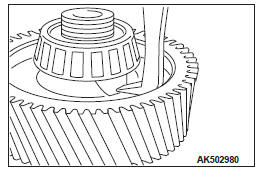

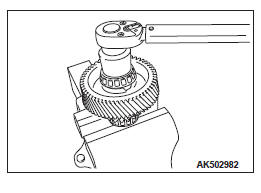

NUT REMOVAL

Remove the nut from the reduction gear sub-assembly.

REDUCTION GEAR BEARING REMOVAL

CAUTION Align the tang of special tool as shown in the diagram.

Using the special tools MB990810, MB990947 and MD999566, remove the inner race of reduction gear bearing (converter housing side) from the reduction gear sub-assembly.

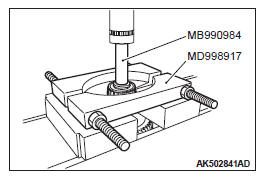

REDUCTION GEAR BEARING REMOVAL

Using the special tools MB990984 and MD998917, remove the outer race of reduction gear bearing (transaxle case side) from the reduction gear sub-assembly.

ASSEMBLY SERVICE POINT

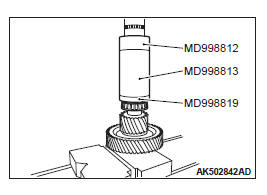

REDUCTION GEAR BEARING INSTALLATION

CAUTION

- Do not re-use the inner race.

- Replace the inner race together with the outer race.

Using the special tools MD998812, MD998813 and MD998819, install the inner race of reduction gear bearing (transaxle case side) on the reduction gear sub-assembly.

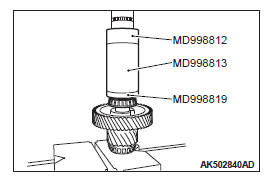

REDUCTION GEAR BEARING INSTALLATION

CAUTION

- Do not re-use the inner race.

- Replace the inner race together with the outer race.

Using the special tools MD998812, MD998813 and MD998819, install the inner race of reduction gear bearing (converter housing side) on the reduction gear sub-assembly.

NUT INSTALLATION

Install the nut on the reduction gear sub-assembly to the specified torque.

Tightening torque: 250 N*m (184 ft-lb)

INSPECTION

REDUCTION GEAR SUB-ASSEMBLY

Measure the inner race press-fit shaft diameter of reduction gear sub-assembly, and replace the assembly if the diameter does not meet the standard value.

Standard values

- Converter housing side

φ30.008 − 30.029 mm (φ1.1814 − 1.1822 in) - Transaxle case side

φ30.008 − 30.029 mm (φ1.1814 − 1.1822 in)

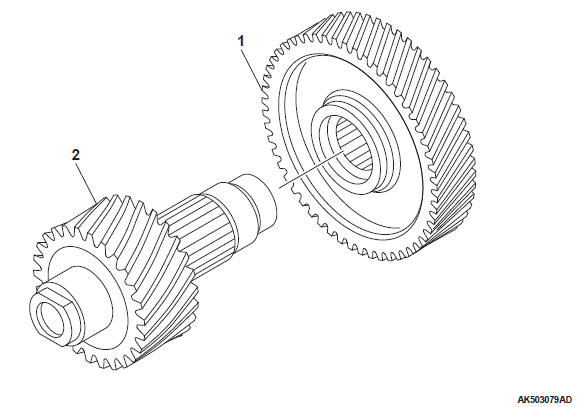

Reduction Gear Sub-assembly

ASSEMBLY

CAUTION The reduction gear sub-assembly can only be assembled, not disassembled.

Assembly steps

- Idler gear

- Reduction pinion gear

Required special tools:

- MD998812: Installer Cap

- MD998813: Installer-100

- MD998819: Installer adapter (40)

ASSEMBLY SERVICE POINT

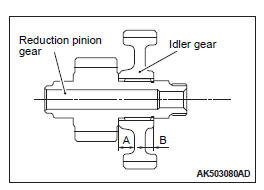

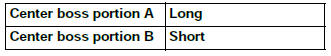

REDUCTION PINION GEAR / IDLER GEAR INSTALLATION

CAUTION When attaching the idler gear to the reduction pinion gear, make sure the center boss portion A faces the reduction pinion gear.

Using the special tools MD998812, MD998813 and MD998819, attach the idler gear to the reduction pinion gear.