Mitsubishi Outlander: Stabilizer Bar

REMOVAL AND INSTALLATION

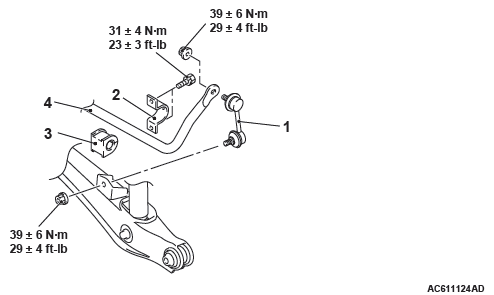

<2.4L Engine: 5 persons seat>

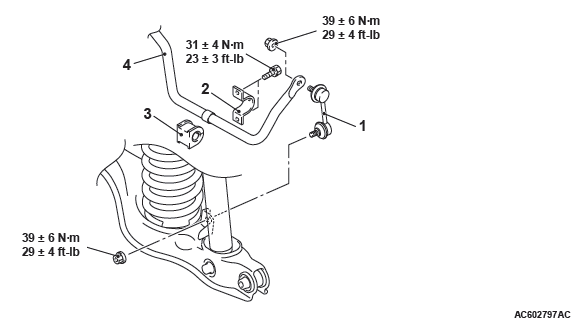

<2.4L Engine: 7 persons seat, 3.0L Engine>

Removal steps

- Stabilizer link

- Stabilizer bracket

- Bushing

- Rear differential carrier assembly

- Stabilizer bar

INSTALLATION SERVICE POINT

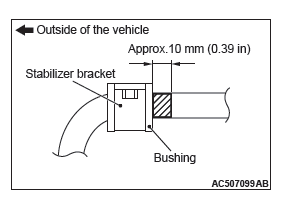

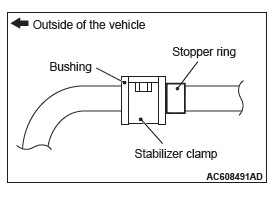

STABILIZER BAR/BUSHING/STABILIZER BRACKET INSTALLATION

<2.4L Engine: 5 persons seat>

Position the identification mark of the stabilizer bar at the left side of the vehicle as shown in the figure, and tighten the stabilizer bracket mounting nut.

<2.4L Engine: 7 persons seat, 3.0L Engine>

Install the stabilizer bracket as shown in the figure, and tighten the stabilizer bracket mounting nut.

INSPECTION

- Check the bushings for wear and deterioration.

- Check the stabilizer bar for deterioration or damage.

- Check all bolts for condition and straightness.

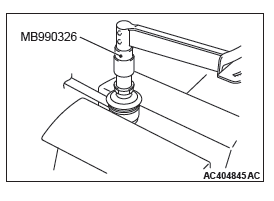

STABILIZER LINK BALL JOINT ROTATION TORQUE CHECK

1. Move the stabilizer link ball joint stud back and forth for several times, install the stud with nut, and measure the stabilizer link ball joint rotation torque using the preload socket (Special tool: MB990326).

Standard value: 0.5 − 2.9 N*m (4.4 − 25.7 in-lb)

2. When the measured value exceeds the standard range, replace the stabilizer link.

3. When the measured value is lower than the standard value, check the stabilizer link ball joint that there is no looseness or gritty feeling. If there is no looseness or gritty feeling, it is judged as usable.

STABILIZER LINK BALL JOINT COVER CHECK

1. Using your fingers, press the dust cover to check for a crack or damage.

2. If the dust cover has a crack or damage, replace the stabilizer link.

NOTE: If the dust cover has a crack or damage, the ball joint could be damaged. If the dust cover is damaged during maintenance, replace it.

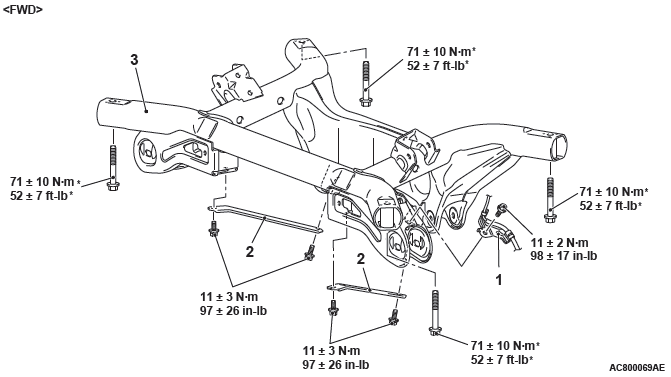

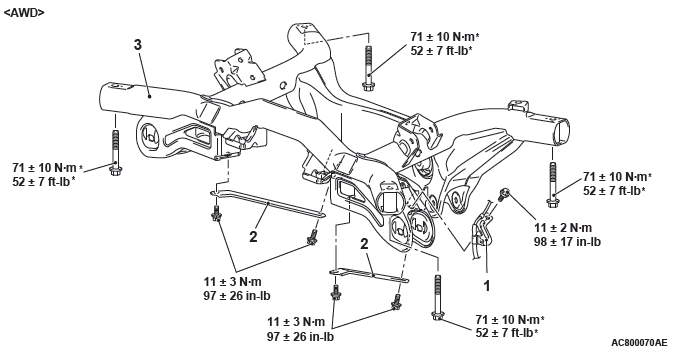

Rear Suspension Crossmember

REMOVAL AND INSTALLATION

CAUTION

- The parts indicated by * are the bolts with friction coefficient stabilizer. In removal, ensure there is no damage, clean dust and soiling from the bearing and thread surfaces, and tighten them to the specified torque.

Pre-removal operation

- Control link arm removal

- Upper arm removal

- Rear suspension stabilizer bar removal

- Center exhaust pipe removal

- Driveshaft removal

- Rear differential assembly removal

Post-installation operation

- Rear differential assembly installation

- Driveshaft installation

- Center exhaust pipe installation

- Rear suspension stabilizer bar installation

- Upper arm installation

- Control link installation

- Rear wheel alignment check and adjustment

<FWD>, <AWD>

Removal steps

- Rear wheel speed sensor clamp

- Rear suspension crossmember stay

- Rear suspension crossmember

REMOVAL SERVICE POINT

REAR SUSPENSION CROSSMEMBER REMOVAL <2.4 L ENGINE: 5 PERSONS SEAT>

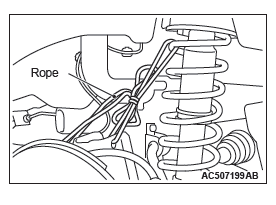

To avoid the break hose load, fix the trailing arm assembly with a rope as shown in the figure.