Mitsubishi Outlander: Transaxle Control

REMOVAL AND INSTALLATION

CAUTION Before removing the clock spring connector, refer to GROUP 52B − SRS Air Bag Service Precautions and Air Bag Module and Clock Spring.

Pre-removal operation

- Front floor console assembly removal

Post-installation operation

- Front floor console assembly installation

- Key interlock mechanism check

- Shift lock mechanism check

- Transmission range switch and control cable adjustment

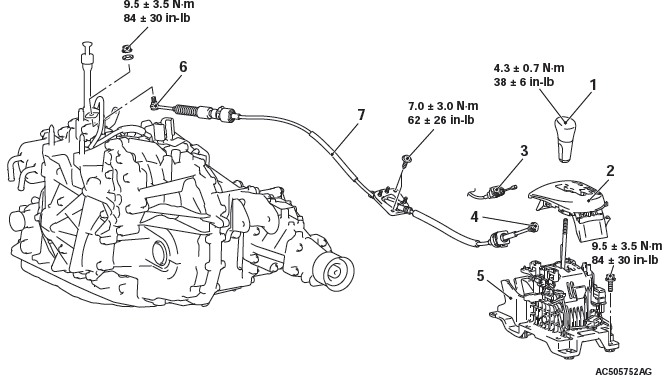

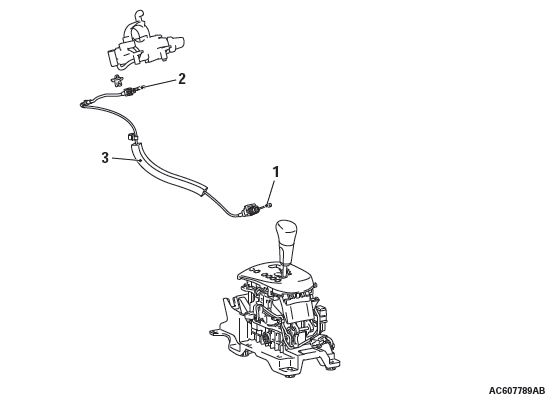

Selector lever assembly and transaxle control cable assembly removal steps

- Move the selector lever to the N position.

- Selector lever knob

- Shift indicator panel

- Key interlock cable connection (selector lever side)

- transaxle control cable connection (selector lever side)

- Connectors and harnesses connections

- Selector lever assembly

- Battery and battery tray

- Air Cleaner

- transaxle control cable connection (transaxle side)

- Heater unit assembly

- transaxle control cable

INSTALLATION SERVICE POINT

KEY INTERLOCK CABLE INSTALLATION

CAUTION Leave the ignition switch in the LOCK (OFF) position until the key interlock cable installation is completed.

1. Move the selector lever to the P position and turn the ignition switch to the LOCK (OFF) position.

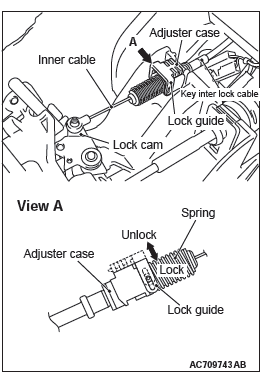

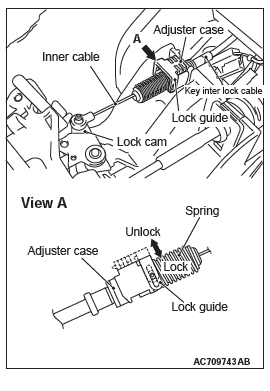

2. Install the tip of the key interlock cable to the lock cam of the selector lever assembly, taking care not to twist the inner cable.

3. Install the adjuster case with its lock guide pulled up (unlocked).

4. Securely push down the lock guide to lock it.

NOTE: The lock position of the key interlock cable is automatically adjusted by a spring.

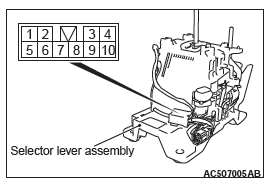

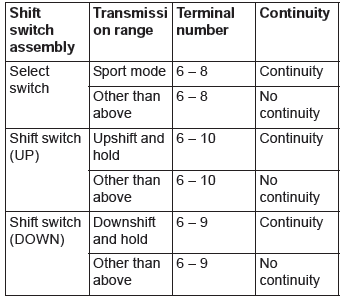

SHIFT SWITCH ASSEMBLY CONTINUITY CHECK

CVT Key Interlock and Shift Lock Mechanisms

REMOVAL AND INSTALLATION

Pre-removal operation

- Steering column lower cover and side lower panel assembly removal

- Front floor console assembly removal

Post-installation operation

- Steering column lower cover and side lower panel assembly installation

- Front floor console assembly installation

- Key interlock mechanism check

- Shift lock mechanism check

- Selector lever operation check

Removal steps

- Key interlock cable connection (selector lever side)

- Key interlock cable connection (steering side)

- Key interlock cable

REMOVAL SERVICE POINT

KEY INTERLOCK CABLE (STEERING SIDE) REMOVAL

Turn the ignition switch to the ACC position and then pull the key interlock cable out from the ignition key cylinder.

INSTALLATION SERVICE POINTS

KEY INTERLOCK CABLE (STEERING LOCK CYLINDER SIDE) INSTALLATION

Turn the ignition switch to the ACC position and then install the key interlock cable to the ignition key cylinder.

KEY INTERLOCK CABLE INSTALLATION

CAUTION Leave the ignition switch in the LOCK (OFF) position until the key interlock cable installation is completed.

1. Move the selector lever to the P position and turn the ignition switch to the LOCK (OFF) position.

2. Install the tip of the key interlock cable to the lock cam of the selector lever assembly, taking care not to twist the inner cable.

3. Install the adjuster case with its lock guide pulled up (unlocked).

4. Securely push down the lock guide to lock it.

NOTE: The lock position of the key interlock cable is automatically adjusted by a spring.