Mitsubishi Outlander: DTC P1637, P1706, P1710, P1723, P1740, P1745, P1773, P1777, P1778, P1902, U0001, U0100, U0121, U0141

DTC P1637: Malfunction of Memory Backup

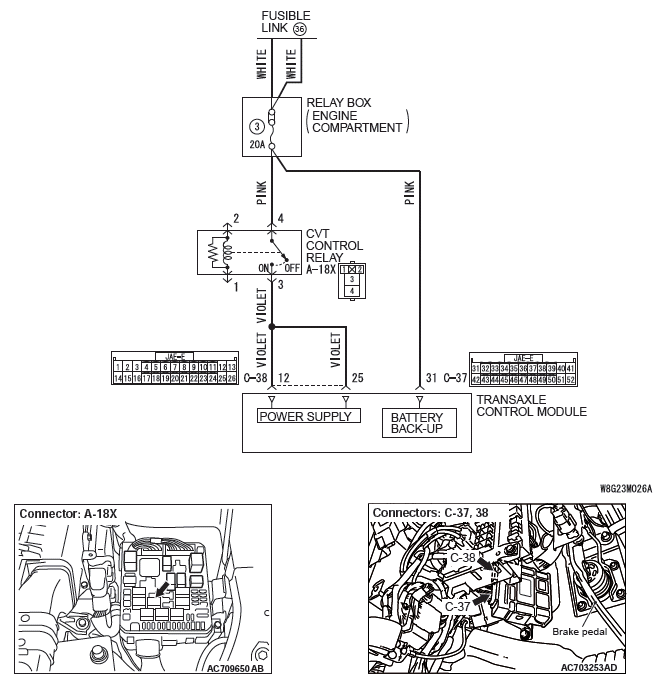

Memory backup system circuit

DIAGNOSTIC FUNCTION

TCM checks the consistency between EEPROM and the backup memory.

DESCRIPTIONS OF MONITOR METHODS

- When the ignition switch is turned to the "ON" position, TCM determines that the writing to the EEPROM area had failed last time the ignition switch was turned to the "LOCK" (OFF) position.

MONITOR EXECUTION

- Continuous

MONITOR EXECUTION CONDITIONS (OTHER MONITOR AND SENSOR)

Other Monitor (There is no temporary DTC stored in memory for the item monitored below)

- Not applicable

Sensor (The sensor below is determined to be normal)

- Not applicable

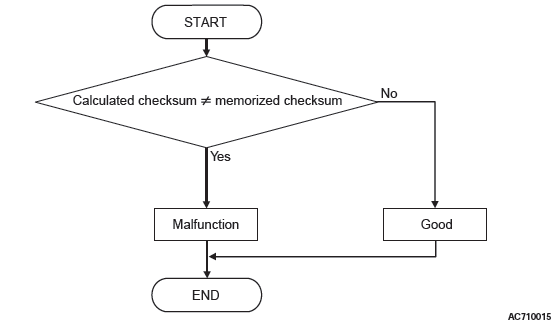

LOGIC FLOW CHARTS (Monitor Sequence)

DTC SET CONDITIONS

JUDGMENT CRITERIA

- Calculated checksum is not same as memorized checksum.

OBD-II DRIVE CYCLE PATTERN

Ignition switch : ON (start the engine and keep it for 10 seconds or more)

PROBABLE CAUSES

- Damaged wiring harness and connectors

- Malfunction of TCM (Faulty EEPROM)

DIAGNOSTIC PROCEDURE

STEP 1. Check if diagnostic trouble code P1637 is erased by turning the ignition switch from the "LOCK" (OFF) position to the "ON" position.

Q: Is the check result normal?

YES : This diagnostic trouble code will be set by disconnecting the battery. If the diagnostic trouble code is not erased by turning the ignition switch to the "ON" position, it is judged to be normal.

NO : Go to Step 2.

STEP 2. Check for open circuit in power supply wiring harness

- Between relay box and C-37 TCM backup power supply connector (terminal No.31)

- Between relay box and A-18X CVT control relay (terminal No.4)

Q: Is the check result normal?

YES : Go to Step 3.

NO : Repair the wiring harness.

STEP 3. Symptom recheck after erasing diagnostic trouble code

Q: Is the check result normal?

YES : Intermittent malfunction

NO : Replace TCM.

DTC P1706: Malfunction of Throttle Signal

DIAGNOSTIC FUNCTION

TCM detects the abnormality in the throttle position signal sent from the ECM.

DESCRIPTIONS OF MONITOR METHODS

- The difference between the throttle position signal received from the ECM and the corresponding turnover value is 1.37 V or more, and this status continues for 1 second.

MONITOR EXECUTION

- Transmission range: D

MONITOR EXECUTION CONDITIONS (OTHER MONITOR AND SENSOR)

Other Monitor (There is no temporary DTC stored in memory for the item monitored below)

- P0705: Malfunction of transmission range switch

- P0715: Malfunction of primary pulley speed sensor

- P0720: Malfunction of secondary pulley speed sensor

- P0725: Malfunction of engine speed

- P0741: Abnormality in lockup function

- P0746: Abnormality in hydraulic control system function

- P0841: Abnormality in line pressure sensor function

Sensor (The sensor below is determined to be normal)

- Transmission range switch

- Primary pulley speed sensor

- Secondary pulley speed sensor

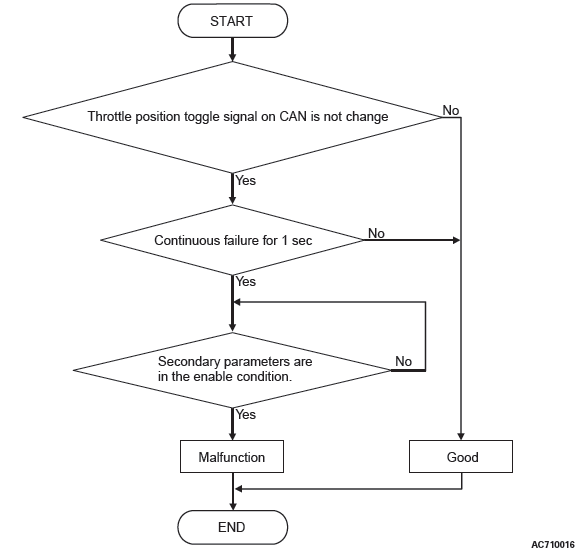

LOGIC FLOW CHARTS (Monitor Sequence)

DTC SET CONDITIONS

Check Conditions

- Transmission range switch position: D.

- Voltage of battery: 9 volts or more.

- Voltage of battery: 16 volts or less.

JUDGMENT CRITERIA

- Throttle position toggle signal on CAN: not change. (1 second)

OBD-II DRIVE CYCLE PATTERN

Ignition switch : ON (start the engine and keep it for 10 seconds or more)

PROBABLE CAUSES

- Malfunction of the CAN bus

- Malfunction of engine system

- Malfunction of TCM

DIAGNOSTIC PROCEDURE

STEP 1. Using scan tool MB991958, diagnose the CAN bus line.

Use scan tool MB991958 to perform the CAN bus diagnosis.

Q: Is the check result normal?

YES : Go to Step 2.

NO : Repair the CAN bus lines.

STEP 2. Scan tool MB991958 diagnostic trouble code

Check if the engine-related diagnostic trouble code is set.

Q: Is diagnostic trouble code set?

YES : Diagnose the engine control system.

NO : Go to Step 3.

STEP 3. Symptom recheck after erasing diagnostic trouble code

Q: Is the check result normal?

YES : Intermittent malfunction

NO : Replace TCM.

DTC P1710: Malfunction of Vehicle Speed Signal

DIAGNOSTIC FUNCTION

TCM conducts fault detection by detecting the rapid change in the estimated vehicle speed signal received from the ABC-ECU.

JUDGMENT CRITERIA

- Difference between the estimated vehicle speed and the one measured before 0.1 second is 29 km/h (18.0 mph) or more.

- The status with the vehicle speed of 10 km/h (6.2 mph) or more and with the estimated vehicle speed of 2 km/h (1.2 mph) or less continues for 20 seconds.

PROBABLE CAUSES

- Malfunction of the CAN bus

- Malfunction of TCM

DIAGNOSTIC PROCEDURE

STEP 1. Troubleshoot the CAN system if diagnosis code U0121 is set.

Q: Is the diagnosis code U0121 set?

YES : Diagnose the CAN system.

NO : Go to Step 2.

STEP 2. M.U.T.-III data list

- Item 21: Vehicle speed (inference)

- Item 22: Real vehicle speed

OK: Vehicle speed signal and vehicle speed do not differ greatly.

Q: Is the check result normal?

YES : Intermittent malfunction

NO : Go to Step 3.

STEP 3. Check ABS-related diagnosis codes.

Q: Is the ABS-related diagnosis code set?

YES : Carry out the appropriate troubleshooting.

NO : Go to Step 4.

STEP 4. Symptom recheck after erasing diagnosis code

Q: Is the check result normal?

YES : Intermittent malfunction

NO : Replace TCM.

DTC P1723: Abnormality in Speed Sensor System Function

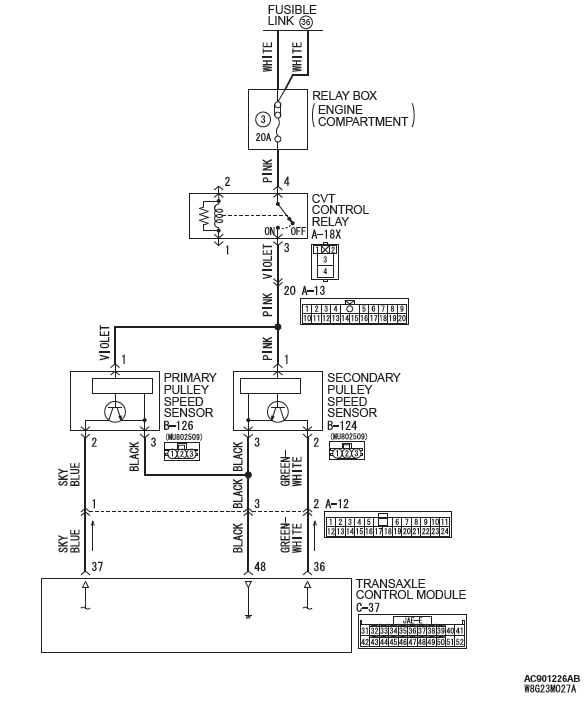

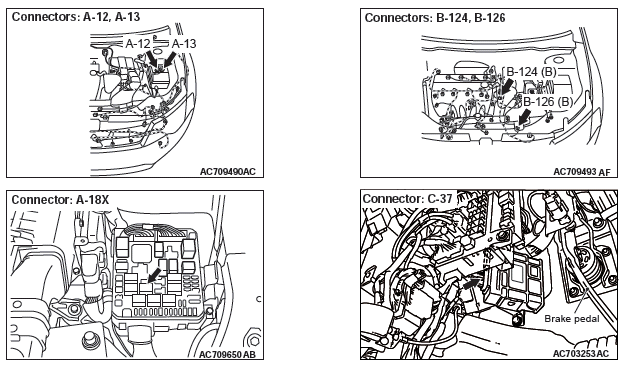

Speed sensor system circuit

DIAGNOSTIC FUNCTION

TCM detects the abnormal wave pattern of the speed sensor signal.

DESCRIPTIONS OF MONITOR METHODS

- Rotational fluctuation of primary pulley is large (for 1 second).

- Rotational fluctuation of secondary pulley is large (for 1 second).

MONITOR EXECUTION

- Continuous

MONITOR EXECUTION CONDITIONS (OTHER MONITOR AND SENSOR)

Other Monitor (There is no temporary DTC stored in memory for the item monitored below)

- P0741: Abnormality in lockup function

- P0746: Abnormality in hydraulic control system function

- P0841: Abnormality in line pressure sensor function

- P0868: Secondary pressure drop

Sensor (The sensor below is determined to be normal)

- Not applicable

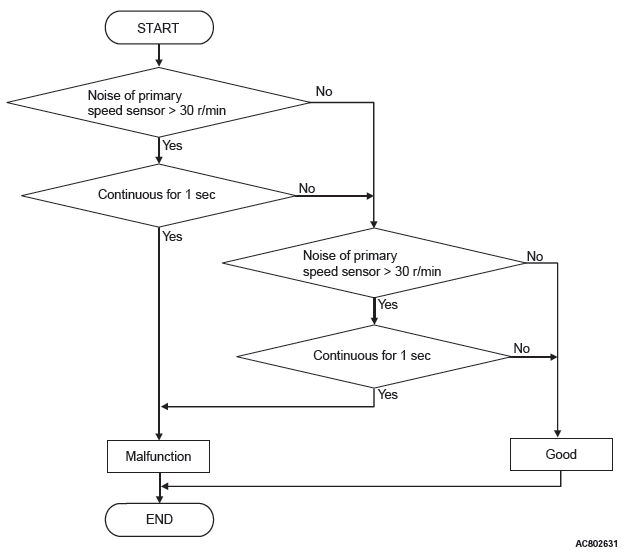

LOGIC FLOW CHARTS (Monitor Sequence)

DTC SET CONDITIONS

Check Conditions

- Voltage of battery: 9 volts or more.

- Voltage of battery: 16 volts or less.

JUDGMENT CRITERIA

- Noise of primary pulley or primary pulley speed sensor signal: more than 30 r/min. (1 second)

- Noise of primary pulley or secondary pulley speed sensor signal: more than 30 r/min. (1 second)

OBD-II DRIVE CYCLE PATTERN

Ignition switch : ON (start the engine and keep it for 10 seconds or more)

PROBABLE CAUSES

- Malfunction of primary pulley speed sensor

- Malfunction of secondary pulley speed sensor

- Malfunction of TCM

DIAGNOSTIC PROCEDURE

STEP 1. Check the following connector:

- C-37 TCM connector

- B-126 Primary pulley speed sensor connector

- B-124 Secondary pulley speed sensor connector

Check for the connection with terminals.

Q: Is the check result normal?

YES : Go to Step 2.

NO : Repair the defective connector.

STEP 2. Use an oscilloscope to measure the wave patterns of the primary pulley speed sensor and secondary pulley speed sensor.

Q: Is the check result normal?

YES : Go to Step 3.

NO : Replace the primary pulley speed sensor or secondary pulley speed sensor.

STEP 3. Symptom recheck after erasing diagnostic trouble code

Q: Is the check result normal?

YES : Intermittent malfunction

NO : Replace TCM.

DTC P1740: Malfunction of Lockup/Select Switching Solenoid Valve

DIAGNOSTIC FUNCTION

TCM detects abnormal operation of the lockup/select switching solenoid valve.

DESCRIPTIONS OF MONITOR METHODS

- Specified amount of current is not flown to the lockup/select switching solenoid valve because of an open or short circuit.

MONITOR EXECUTION

- Continuous

MONITOR EXECUTION CONDITIONS (OTHER MONITOR AND SENSOR)

Other Monitor (There is no temporary DTC stored in memory for the item monitored below)

- P0741: Abnormality in lockup function

- P0746: Abnormality in hydraulic control system function

- P0841: Abnormality in line pressure sensor function

Sensor (The sensor below is determined to be normal)

- Not applicable

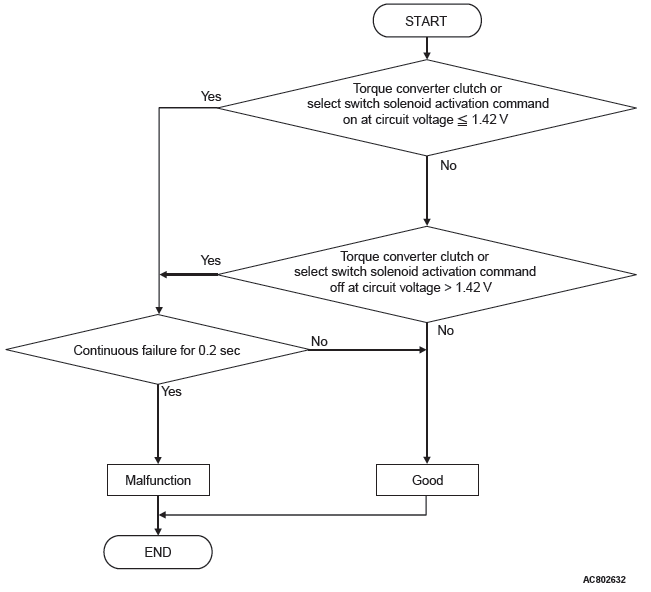

LOGIC FLOW CHARTS (Monitor Sequence)

DTC SET CONDITIONS

Judgment Criteria

- Lockup/select switching solenoid valve activation command (ON voltage): 1.42 volts or less (0.2 second)

- Lockup/select switching solenoid valve activation command (OFF voltage): more than 1.42 volts (0.2 second)

OBD-II DRIVE CYCLE PATTERN

Ignition switch : ON (start the engine and keep it for 10 seconds or more)

PROBABLE CAUSES

- Malfunction of valve body assembly (Faulty lockup/select switching solenoid valve)

- Damaged wiring harness and connectors

- Malfunction of TCM

PROBABLE CAUSES

- Malfunction of valve body assembly (Faulty lockup/select switching solenoid valve)

- Damaged wiring harness and connectors

- Malfunction of TCM

DIAGNOSTIC PROCEDURE

STEP 1. M.U.T.-III data list

- Item 36: LU/SEL changeover SOL. output

- Item 37: LU/SEL changeover SOL. monitor

OK: Check that the output and monitor do not differ greatly.

Q: Is the check result normal?

YES : Intermittent malfunction

NO : Go to Step 2.

STEP 2. Check the following connector:

- B-125 CVT assembly connector

- C-38 TCM connector

- A-12 Intermediate connector

Check the terminals for a contact status problem and internal short circuit.

Q: Is the check result normal?

YES : Go to Step 3.

NO : Repair the defective connector.

STEP 3. Check for open circuit and short to ground in the wiring harness between the TCM connector and the CVT assembly connector.

Between C-38 TCM connector (terminal No.14) and B-125 CVT assembly connector (terminal No.4)

Q: Is the check result normal?

YES : Go to Step 4.

NO : Repair the wiring harness.

STEP 4. Lockup/select switching solenoid valve single unit check

Q: Is the check result normal?

YES : Go to Step 5.

NO : Replace the valve body assembly.

STEP 5. Symptom recheck after erasing diagnostic trouble code

Q: Is the check result normal?

YES : Intermittent malfunction

NO : Replace TCM.

DTC P1745: Monitoring of Percentage Change in Pulley Ratio

DIAGNOSTIC FUNCTION

TCM conducts fault detection by monitoring the internal calculated value.

JUDGEMENT CRITERIA

Percentage change in pulley ratio is larger than the standard value.

PROBABLE CAUSES

- Malfunction of TCM

DIAGNOSTIC PROCEDURE

STEP 1. Symptom recheck after erasing diagnosis code

Q: Is the check result normal?

YES : Intermittent malfunction

NO : Replace TCM.

DTC P1773: Malfunction of ABS

DIAGNOSTIC FUNCTION

TCM detects the ABS abnormality.

DESCRIPTIONS OF MONITOR METHODS

- When the ABS error signal reception continues for 0.5 seconds.

MONITOR EXECUTION

- When 1.05 seconds have elapsed after TCM started (not during M.U.T.-III communication)

MONITOR EXECUTION CONDITIONS (OTHER MONITOR AND SENSOR)

Other Monitor (There is no temporary DTC stored in memory for the item monitored below)

- Not applicable

Sensor (The sensor below is determined to be normal)

- Not applicable

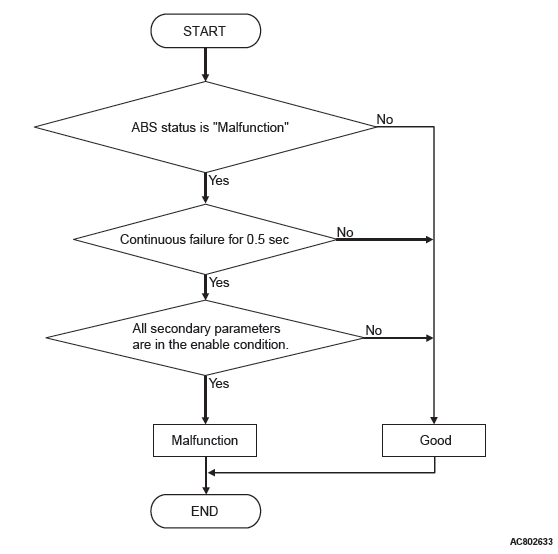

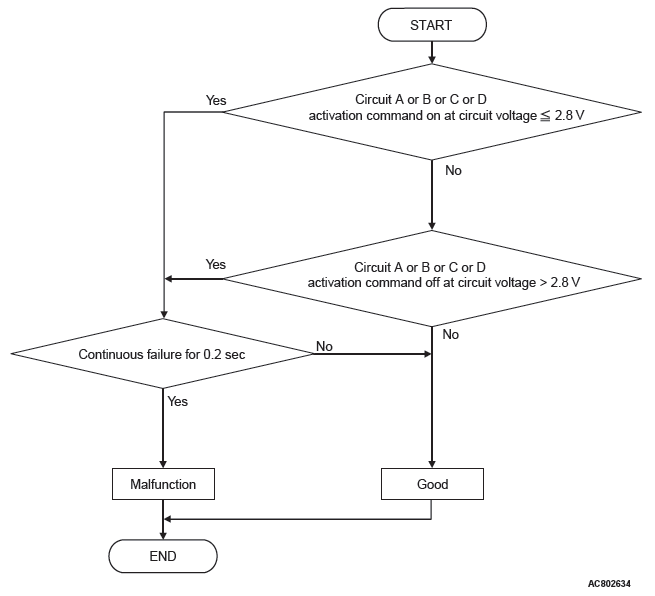

LOGIC FLOW CHARTS (Monitor Sequence)

DTC SET CONDITIONS

Check Conditions

- Time after TCM start: more than 1.05 seconds.

Judgment Criteria

- ABS status: malfunction

OBD-II DRIVE CYCLE PATTERN

Ignition switch : ON (start the engine and keep it for 10 seconds or more, not during M.U.T.-III communication)

PROBABLE CAUSES

- Malfunction of the ABS system

- Malfunction of TCM

DIAGNOSTIC PROCEDURE

STEP 1. ABS system DTC check

Q: Is the ABS system DTC set?

YES : Carry out the troubleshooting for ABS.

NO : Go to Step 2.

STEP 2. Symptom recheck after erasing diagnosis code

Q: Is the check result normal?

YES : Intermittent malfunction

NO : Replace TCM.

DTC P1777: Malfunction of Stepper Motor

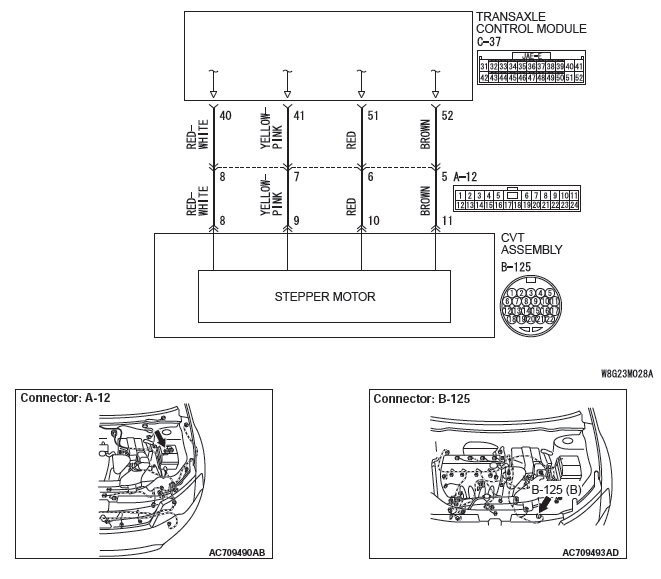

Stepper motor system circuit

DIAGNOSTIC FUNCTION

TCM conducts fault detection by monitoring the voltage of each coil for stepper motors.

DESCRIPTIONS OF MONITOR METHODS

- The specified voltage is not applied to each coil for stepper motors for 0.2 second because of an open or short circuit.

MONITOR EXECUTION

- Continuous

MONITOR EXECUTION CONDITIONS (OTHER MONITOR AND SENSOR)

Other Monitor (There is no temporary DTC stored in memory for the item monitored below)

- P0741: Abnormality in lockup function

- P0746: Abnormality in hydraulic control system function

- P0841: Abnormality in line pressure sensor function

- P0868: Secondary pressure drop

Sensor (The sensor below is determined to be normal)

- Not applicable

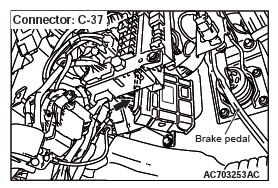

LOGIC FLOW CHARTS (Monitor Sequence)

DTC SET CONDITIONS

JUDGMENT CRITERIA

- Stepping motor activation command (ON voltage): 2.8 volts or less. (0.2 second)

- Stepping motor activation command (OFF voltage): More than 2.8 volts. (0.2 second)

OBD-II DRIVE CYCLE PATTERN

Ignition switch : ON (start the engine and keep it for 10 seconds or more)

PROBABLE CAUSES

- Malfunction of valve body assembly (Faulty stepper motor)

- Damaged wiring harness and connectors

- Malfunction of TCM

DIAGNOSTIC PROCEDURE

STEP 1. Check the following connector:

- B-125 CVT assembly connector

- C-37 TCM connector

Check the terminals for a contact status problem and internal short circuit.

Q: Is the check result normal?

YES : Go to Step 2.

NO : Repair the defective connector.

STEP 2. Check for open circuit and short to ground in the wiring harness between the TCM connector and the stepper motor.

- Between TCM connector (terminal No.40) and body ground

- Between TCM connector (terminal No.41) and body ground

- Between TCM connector (terminal No.51) and body ground

- Between TCM connector (terminal No.52) and body ground

OK: Resistance value is approximately 15 Ω.

Q: Is the check result normal?

YES : Go to Step 4.

NO : Go to Step 3.

STEP 3. Check for open circuit and short to ground in the wiring harness between TCM and the stepper motor

- Between C-37 TCM connector (terminal No.40) and B-125 CVT assembly connector (terminal No.8)

- Between C-37 TCM connector (terminal No.41) and B-125 CVT assembly connector (terminal No.9)

- Between C-37 TCM connector (terminal No.51) and B-125 CVT assembly connector (terminal No.10)

- Between C-37 TCM connector (terminal No.52) and B-125 CVT assembly connector (terminal No.11)

Check that there is no continuity in both sides of the connectors and that no short circuit is present between the connectors and the body ground.

Q: Is the check result normal?

YES : Replace the valve body assembly.

NO : Repair the wiring harness.

STEP 4. Symptom recheck after erasing diagnostic trouble code

Q: Is the check result normal?

YES : Intermittent malfunction

NO : Replace TCM.

DTC P1778: Abnormality In Stepper Motor Function

DIAGNOSTIC FUNCTION

TCM conducts the fault detection of the stepper motor by comparing the target value of the primary pulley speed with the actual value. (Target value: Actual secondary pulley speed multiplied by pulley ratio corresponding to stepper motor position) (Actual measurement value: Actual primary pulley speed)

JUDGEMENT CRITERIA

The difference between the target value of the primary pulley speed and the actual measurement value is greater than the standard value, the difference between the target pulley ratio and the actual pulley ratio is 0.3 or greater, and this status continues for 5 seconds.

PROBABLE CAUSES

- Malfunction of TCM

- Malfunction of valve body assembly (Faulty stepper motor)

DIAGNOSTIC PROCEDURE

STEP 1. Check other diagnosis codes.

Q: Are other diagnosis codes set?

YES : Carry out the appropriate troubleshooting.

NO : Go to Step 2.

STEP 2. Symptom recheck after erasing diagnosis code

Q: Is the check result normal?

YES : Intermittent malfunction

NO : Replace the TCM, and then go to Step 3.

STEP 3. Retest the system.

Q: Is the check result normal?

YES : The inspection is complete.

NO : Replace the valve body assembly.

DTC P1902: Malfunction of Engine System

DIAGNOSTIC FUNCTION

- When the ECM detects the malfunction of the ETV system, the ECM enters the limp-home control mode (throttle valve angle: approximately 20%).

- TCM begins controlling the following items: lockup inhibition, increase of secondary pressure, fixing of pulley ratio line.

JUDGEMENT CRITERIA

TCM receives the limp-home signal from ECM via CAN.

PROBABLE CAUSES

- Malfunction of the engine system (ETV)

DIAGNOSIS PROCEDURE

STEP 1. Check the engine-related diagnosis code.

Q: Is the engine-related diagnosis code set?

YES : Carry out the appropriate troubleshooting.

NO : Go to Step 2.

STEP 2. Symptom recheck after erasing diagnosis code

Q: Is the check result normal?

YES : Intermittent malfunction

NO : Replace the TCM.

DTC U0001: Malfunction of CAN Communication Circuit

DIAGNOSTIC FUNCTION

TCM conducts bus-off detection.

DESCRIPTIONS OF MONITOR METHODS

- TCM cannot receive the periodic communication data.

MONITOR EXECUTION

- When 1.05 seconds have elapsed after TCM started

MONITOR EXECUTION CONDITIONS (OTHER MONITOR AND SENSOR)

Other Monitor (There is no temporary DTC stored in memory for the item monitored below)

- P0703: Malfunction of stoplight switch

- P0705: Malfunction of transmission range switch

- P0715: Malfunction of primary pulley speed sensor

- P0720: Malfunction of secondary pulley speed sensor

- P0725: Malfunction of engine speed

- P0741: Abnormality in lockup function

- P0746: Abnormality in hydraulic control system function

- P0841: Abnormality in line pressure sensor function

- P0868: Secondary pressure drop

- P1706: Malfunction of throttle signal

- P1773: Malfunction of ABS

- U0100: CAN time-out error (Engine)

Sensor (The sensor below is determined to be normal)

- Stoplight switch

- Transmission range switch

- Primary pulley speed sensor

- Secondary pulley speed sensor

LOGIC FLOW CHARTS (Monitor Sequence)

DTC SET CONDITIONS

Check Conditions

- Time after TCM start: more than 1.05 seconds.

- Voltage of battery: 9 volts or more

- Voltage of battery: 16 volts or less

Judgment Criteria

- CAN communication: fail

OBD-II DRIVE CYCLE PATTERN

Ignition switch : ON (start the engine and keep it for 10 seconds or more)

PROBABLE CAUSES

- Malfunction of the CAN bus

DIAGNOSTIC PROCEDURE

STEP 1. M.U.T.-III CAN bus diagnostics

Use M.U.T.-III to perform the CAN bus diagnosis.

Q: Is the check result normal?

YES : Intermittent malfunction

NO : Repair the CAN bus lines (Refer to GROUP 54C − Troubleshooting, Diagnosis Code Chart).

DTC U0100: CAN Time-out Error (Engine)

DIAGNOSTIC FUNCTION

TCM receives periodic communication data from the ECM via CAN bus lines.

JUDGMENT CRITERIA

TCM cannot receive the periodic communication data from the ECM.

DESCRIPTIONS OF MONITOR METHODS

- TCM cannot receive the periodic communication data from the ECM.

MONITOR EXECUTION

- When 1.05 seconds have elapsed after TCM started

MONITOR EXECUTION CONDITIONS (OTHER MONITOR AND SENSOR)

Other Monitor (There is no temporary DTC stored in memory for the item monitored below)

- P0725: Malfunction of engine speed

- P0868: Secondary pressure drop

Sensor (The sensor below is determined to be normal)

- Not applicable

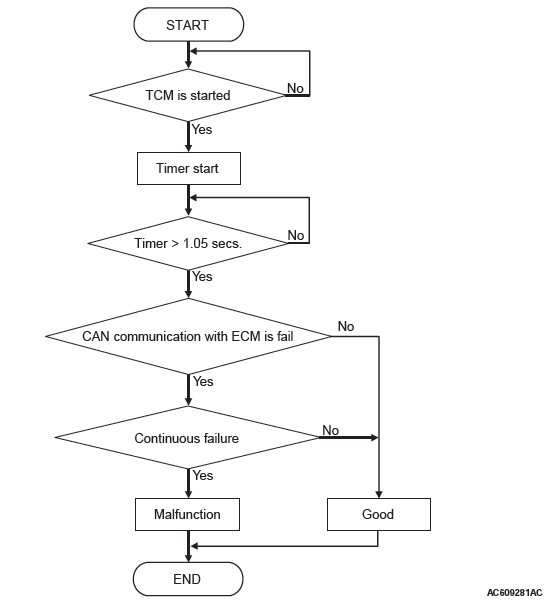

LOGIC FLOW CHARTS (Monitor Sequence)

DTC SET CONDITIONS

Check Conditions

- Time after TCM start: more than 1.05 seconds.

- Voltage of battery: 9 volts or more

- Voltage of battery: 16 volts or less

JUDGMENT CRITERIA

- CAN communication with ECM: fail. (500 millisecond)

OBD-II DRIVE CYCLE PATTERN

Ignition switch : ON (start the engine and keep it for 10 seconds or more)

PROBABLE CAUSES

- Malfunction of the CAN bus

- Engine ECU malfunction

- Malfunction of TCM

DIAGNOSTIC PROCEDURE

STEP 1. Using scan tool MB991958, diagnose the CAN bus line.

Use scan tool MB991958 to perform the CAN bus diagnosis.

Q: Is the check result normal?

YES : Go to Step 2.

NO : Repair the CAN bus lines.

STEP 2. Scan tool MB991958 diagnostic trouble code

Check if the engine-related diagnostic trouble code is set.

Q: Is the engine-related diagnostic trouble code set?

YES : Carry out the appropriate troubleshooting.

NO : Go to Step 3.

STEP 3. Symptom recheck after erasing diagnostic trouble code

Q: Is the check result normal?

YES : Intermittent malfunction

NO : Replace TCM.

DTC U0121: CAN Time-out Error (ABS)

DIAGNOSTIC FUNCTION

TCM determines that malfunction is present if the periodic communication data sent from the ABS-ECU via CAN bus lines is abnormal.

JUDGMENT CRITERIA

TCM cannot receive the periodic communication data from ABS-ECU.

PROBABLE CAUSES

- Malfunction of the CAN bus

- ABS-ECU malfunction

- Malfunction of TCM

DIAGNOSTIC PROCEDURE

STEP 1. Using scan tool MB991958, diagnose the CAN bus line.

Use scan tool MB991958 to perform the CAN bus diagnosis.

Q: Is the check result normal?

YES : Go to Step 2.

NO : Repair the CAN bus lines (Refer to GROUP 54C − Troubleshooting, Diagnostic Trouble Code Chart).

STEP 2. Scan tool MB991958 diagnostic trouble code

Check if the ABS-related diagnostic trouble code is set.

Q: Is the ABS-related diagnostic trouble code set?

YES : Carry out the appropriate troubleshooting.

NO : Go to Step 3.

STEP 3. Symptom recheck after erasing diagnostic trouble code

Q: Is the check result normal?

YES : Intermittent malfunction

NO : Replace TCM.

DTC U0141: CAN Time-out Error (ETACS)

DIAGNOSTIC FUNCTION

TCM determines that malfunction is present if the periodic communication data sent from ETACS-ECU via the CAN bus lines is abnormal.

JUDGMENT CRITERIA

TCM cannot receive the periodic communication data from ETACS-ECU.

PROBABLE CAUSES

- Malfunction of the CAN bus

- Malfunction of ETACS-ECU

- Malfunction of TCM

DIAGNOSTIC PROCEDURE

STEP 1. Using scan tool MB991958, diagnose the CAN bus line.

Use scan tool MB991958 to perform the CAN bus diagnosis.

Q: Is the check result normal?

YES : Go to Step 2.

NO : Repair the CAN bus lines. (Refer to GROUP 54C − Troubleshooting, Diagnostic Trouble Code Chart)

STEP 2. Scan tool MB991958 diagnostic trouble code

Check if ETACS-related diagnostic trouble code is set.

Q: Is the ECU-related diagnostic trouble code set?

YES : Carry out the appropriate troubleshooting.

NO : Go to Step 3.

STEP 3. Symptom recheck after erasing diagnostic trouble code

Q: Is the check result normal?

YES : Intermittent malfunction NO : Replace TCM.