Mitsubishi Outlander: Engine Cooling

General Information

The cooling system is designed to keep every part of

the engine at appropriate temperature in whatever

condition the engine may be operated. The cooling

method is of the water-cooled, pressure forced circulation

type in which the water pump pressurizes coolant

and circulates it throughout the engine. If the

coolant temperature exceeds the prescribed temperature,

the thermostat opens to circulate the coolant

through the radiator as well so that the heat

absorbed by the coolant may be radiated into the air.

The water pump is of the centrifugal impeller type

and is driven by the drive belt from the crankshaft

<2.4L ENGINE>. The water pump is of the centrifugal

impeller type and is driven by the timing belt from

the crankshaft <3.0L ENGINE>. The radiator is the

corrugated fin, cross flow type.

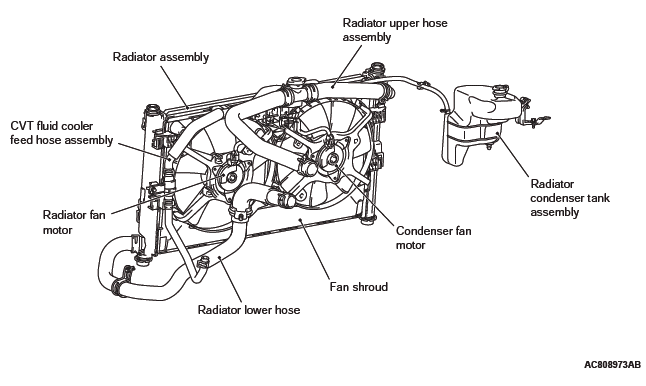

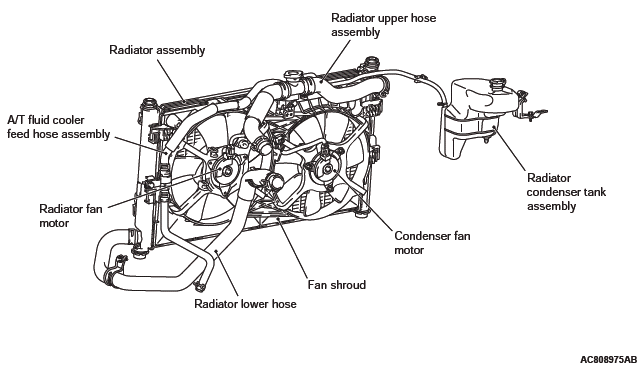

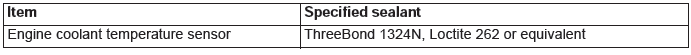

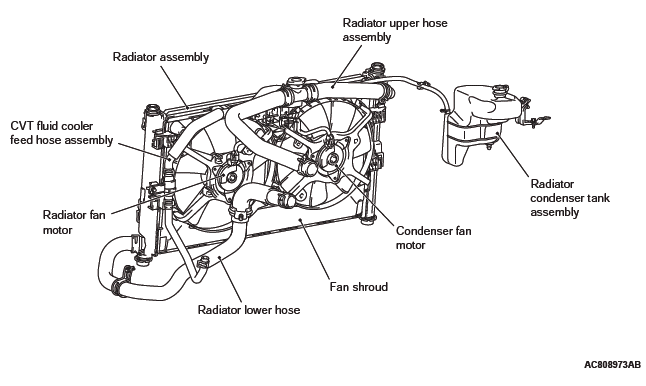

CONSTRUCTION DIAGRAM

<2.4L ENGINE>

<3.0L ENGINE>

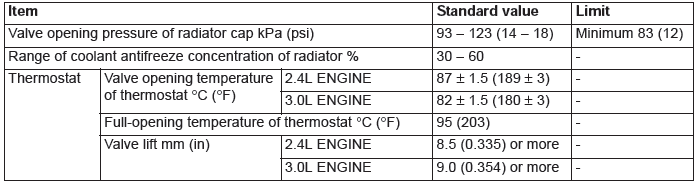

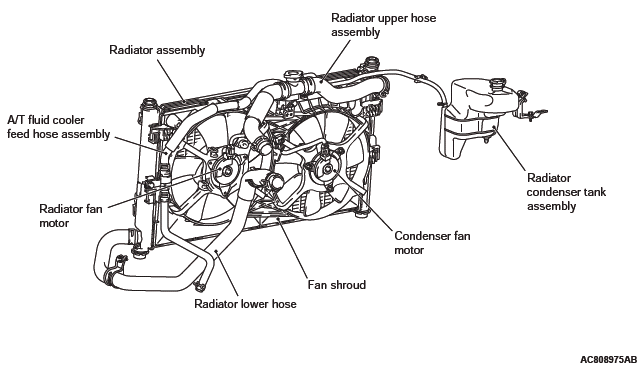

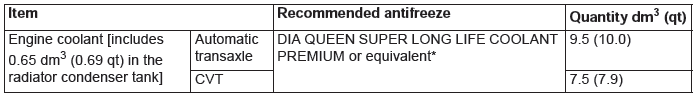

Service Specifications

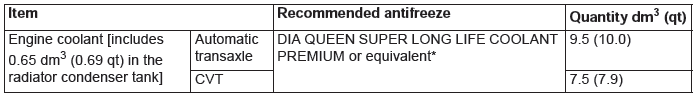

Coolant

NOTE: *similar high quality ethylene glycol based non-silicate, non-amine,

non-nitrate and non-borate coolant

with long life hybrid organic acid technology.

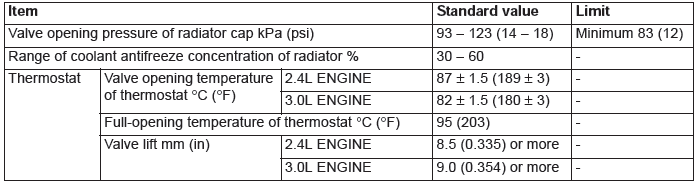

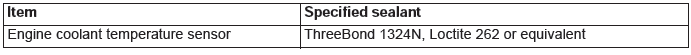

Sealant

READ NEXT:

INTRODUCTION

The system cools the engine so that it does not overheat

and maintains the engine at an optimum temperature.

The system components are the radiator,

water pump, thermostat, condenser fa

ENGINE COOLANT LEAK CHECK

WARNING

When pressure testing the cooling system, slowly

release cooling system pressure to avoid getting

burned by hot coolant.

CAUTION

Be sure to completely clean away a

REMOVAL AND INSTALLATION <2.4L ENGINE>

Pre-removal Operation

Engine Coolant Draining

Engine Upper Cover Removal

Air Cleaner Assembly Removal

Post-installation Operation

Air Cleaner Asse

SEE MORE:

If the engine cannot be started because the battery is weak or dead, the battery

from another vehicle can be used with jumper cables to start the engine.

WARNING:

● To start the engine using jumper cables connected to another vehicle, perform

the correct procedures according to the instr

REMOVAL AND INSTALLATION <2.4L ENGINE>

Pre-removal operation

Engine coolant Draining

Air Cleaner Assembly Removal

Post-installation operation

Air Cleaner Assembly Installation

Engine Coolant Refilling and Check

Radiator removal steps

Engine room under cover front

Radiator drain

© 2010-2025 Copyright www.mioutlander.com