Mitsubishi Outlander: Side Cover

DISASSEMBLY AND ASSEMBLY

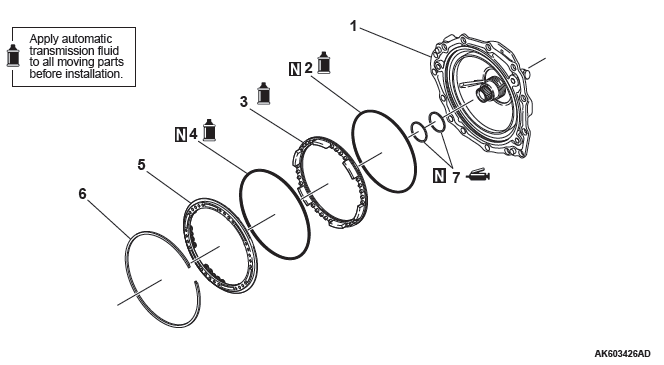

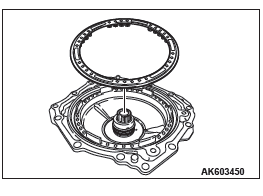

- Side cover

- D-ring

- 2-6 brake piston

- D-ring

- Spring retainer

- Snap ring

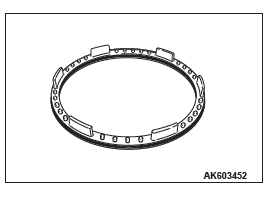

- Seal ring

Required special tools:

- MB992196: Spring compressor

DISASSEMBLY

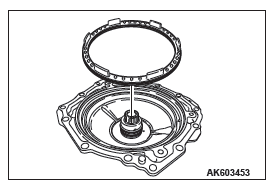

1. Remove the seal rings from the side cover.

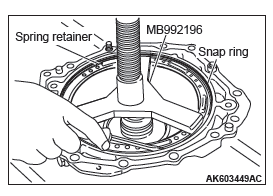

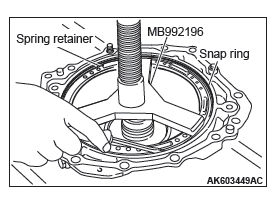

CAUTION Ensure that the special tool MB992196 is correctly set, directly above the return springs of the spring retainer assembly.

2. Using the special tool MB992196, remove the snap ring while pushing the spring retainer assembly.

CAUTION Do not remove the return springs from the spring retainer assembly.

3. Remove the spring retainer assembly from the 2-6 brake piston.

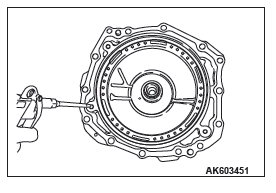

CAUTION Do not feed air abruptly. Otherwise, the 2-6 brake piston may become stuck in the side cover.

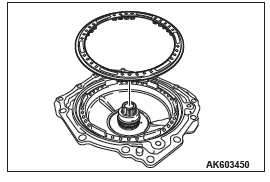

4. Feed air through the oil hole as indicated in the illustration to remove the 2-6 brake piston from the side cover.

5. Remove the D-rings from the 2-6 reverse brake piston.

ASSEMBLY

CAUTION

- Never reuse the D-rings.

- Apply transmission fluid to the D-rings before installation.

1. Install D-rings onto the 2-6 brake piston.

CAUTION Apply transmission fluid to the 2-6 brake piston before installation.

2. Install the 2-6 brake piston onto the side cover.

3. Install the spring retainer assembly onto the 2-6 brake piston.

CAUTION Ensure that the special tool MB992196 is correctly set, directly above the return springs of the spring retainer assembly.

4. Using the special tool MB992196, install the snap ring while pushing the spring retainer assembly.

CAUTION

- Never reuse the seal rings.

- Apply vaseline to the seal rings before installation.

5. Install seal rings onto the side cover.