Mitsubishi Outlander: Timing Chain

REMOVAL AND INSTALLATION

Pre-removal operation

- Engine Room Under Cover Front B and Engine Room Side Cover (RH) Removal

- Engine Oil Draining

- Rocker Cover Assembly Removal

- Engine Oil Pan Removal

Post-installation operation

- Engine Oil Pan Installation

- Rocker Cover Assembly Installation

- Engine Oil Refilling

- Engine Room Under Cover Front B and Engine Room Side Cover (RH) Installation

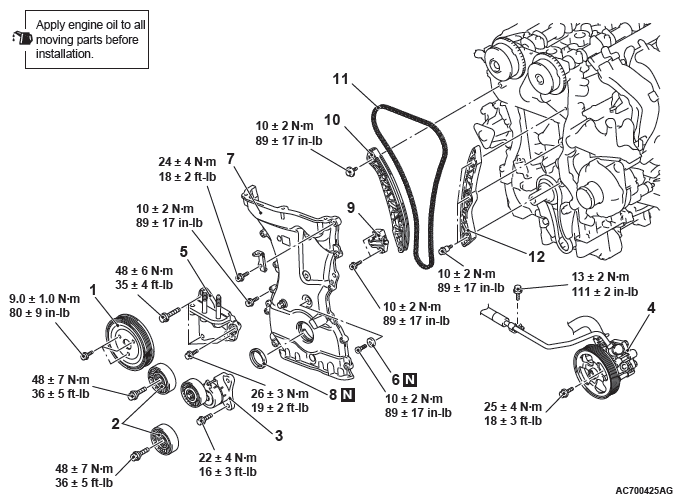

Removal steps

- Crankshaft pulley

- Water pump pulley

- Idler pulley

- Auto-tensioner

- Power steering oil pump assembly

- Engine and transaxle assembly holding

- Engine mounting insulator

- Cylinder block engine front mounting bracket

- Gasket

- Timing chain case assembly

- Crankshaft front oil seal

- Timing chain tensioner

- Timing chain tension side guide

- Timing chain

- Timing chain loose side guide

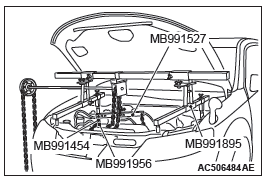

Required Special Tools:

- MB991956: Engine Hanger Plate

- MB991527: Hanger

- MB991454: Engine Hanger Balancer

- MB991895: Engine Hanger

- MB991928: Engine Hanger

- MB991448: Bush Remover and Installer Base

REMOVAL SERVICE POINTS

CRANKSHAFT PULLEY REMOVAL

When removing the crankshaft pulley, slightly loosen the water pump pulley mounting bolts before removal of the drive belt.

POWER STEERING OIL PUMP ASSEMBLY REMOVAL

1. With the hose installed, remove the power steering oil pump assembly from the bracket.

2. Tie the removed power steering oil pump assembly with a string at a position where it will not interfere with the removal and installation of valve timing chain.

ENGINE AND TRANSAXLE ASSEMBLY HOLDING

Install a special tool for holding the engine and transaxle assembly.

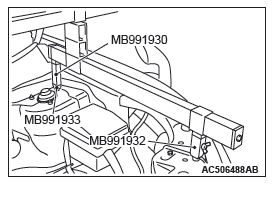

1. <Engine hanger MB991928 is used>

- Assemble special tool engine hanger (MB991928) (Set

the following parts on the base hanger).

- Slide bracket (HI)

- Foot x 2 (standard) (MB991932)

- Foot x 2 (short) (MB991933)

- Joint x 2 (90) (MB991930)

- Set the foot of the special tools (MB991930, MB991932 and MB991933) as shown in the figure.

NOTE: Slide the slide bracket (HI) to adjust the engine hanger balance.

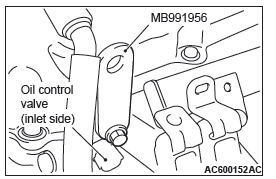

- Install special tool MB991956 to the cylinder head, and set special tool MB991527 and the chains of special tool MB991454 to the engine assembly to hold the engine and transaxle assembly.

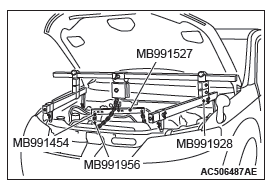

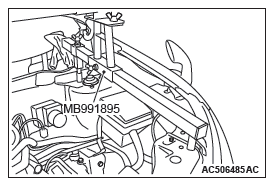

2. <Engine hanger MB991895 is used>

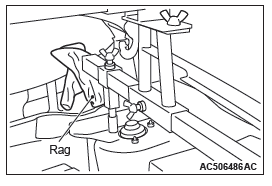

CAUTION

Place a rag between special tool MB991895 and the windshield to prevent the special tool MB991895 from interfering with the windshield.

- Set the foot of special tool MB991895 as shown in the figure.

NOTE: Slide the foot to adjust the engine hanger balance.

- Install special tool MB991956 to the cylinder head, and set special tool MB991527 and the chains of special tool MB991454 to the engine assembly to hold the engine and transaxle assembly.

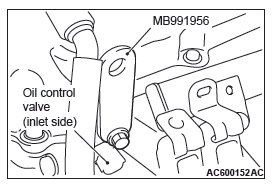

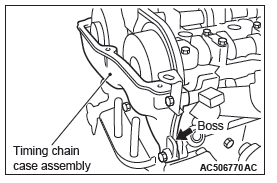

TIMING CHAIN CASE ASSEMBLY REMOVAL

CAUTION

If the adhesive strength of sealant on the timing chain case assembly is so strong that the boss may be damaged by peeling off, do not peel it off forcibly.

1. After removing the timing chain case assembly mounting bolts, slightly pry the boss of the timing chain case assembly shown in the figure using a flat-tipped screwdriver (−), and remove the timing chain case assembly from the cylinder head and cylinder block.

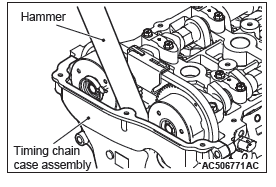

2. If the sealant cannot be peeled off easily, insert a wooden hammer shank into the timing chain case assembly inside as shown in the figure, pry slightly, and remove the timing chain case assembly from the cylinder head and cylinder block.

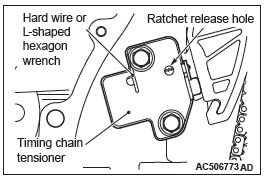

TIMING CHAIN TENSIONER REMOVAL

1. Temporarily install the crankshaft pulley to the crankshaft.

CAUTION

Never turn the crankshaft counterclockwise.

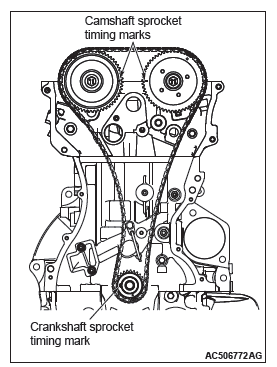

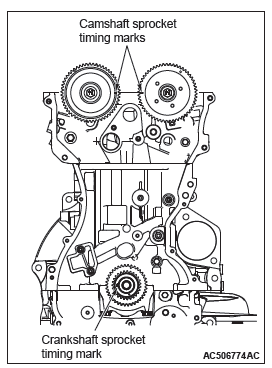

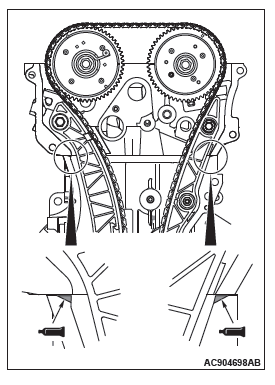

2. Turn the crankshaft clockwise to align the sprocket timing marks as shown in the figure and set the cylinder No.1 to the top dead center of compression stroke.

NOTE: At this time, it is not necessary that the link plate (orange or blue) of the timing chain always aligns with each sprocket timing mark.

3. Remove the crankshaft pulley installed temporarily.

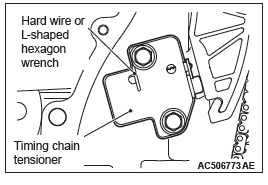

4. Using a flat-tipped precision screwdriver, release the ratchet of timing chain tensioner.

5. Compress the plunger of timing chain tensioner and insert hard wire (such as piano wire) or the L-shaped hexagon wrench (1.5 mm [0.05 inch] ) to fix the plunger of the timing chain tensioner.

6. Remove the timing chain tensioner.

INSTALLATION SERVICE POINTS

TIMING CHAIN INSTALLATION

1. Set the timing marks of the camshaft sprockets and the crankshaft sprocket as shown in the figure.

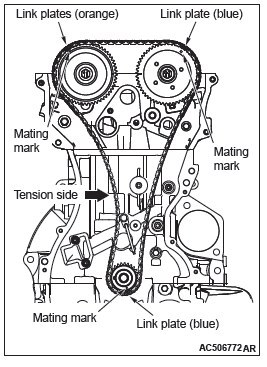

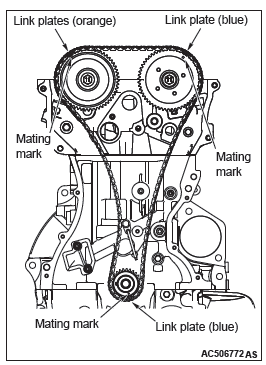

2. Align each sprocket timing chain mating mark with the link plate (orange or blue) of timing chain to avoid slack of the timing chain tension side, and install the timing chain to the sprockets.

TIMING CHAIN TENSIONER INSTALLATION

1. Check that the sprocket timing chain mating marks align with the link plates (orange or blue) of the timing chain, and install the timing chain tensioner to the cylinder block.

2. Remove the hard wire or L-shaped hexagon wrench fixing the plunger of the timing chain tensioner to apply tension to the timing chain.

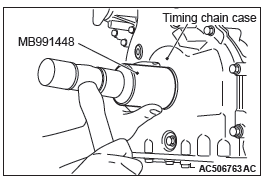

CRANKSHAFT FRONT OIL SEAL INSTALLATION

1. Apply a small amount of engine oil to the entire inner diameter of the crankshaft front oil seal lip.

CAUTION

When installing the crankshaft front oil seal, be careful to avoid damage to the crankshaft front oil seal.

2. Using special tool MB991448, press in the crankshaft front oil seal up to the chamfered surface of timing chain case.

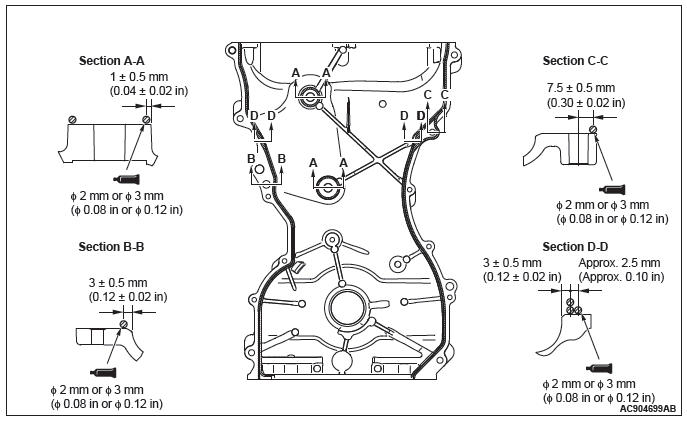

TIMING CHAIN CASE ASSEMBLY INSTALLATION

CAUTION

- Be sure to remove the sealant inside the mounting holes and the O-ring grooves.

- After degreasing with white gasoline or the like, check that there is no oil on the surface where the sealant is applied.

- After degreasing with white gasoline or the like, never touch the degreased area with fingers.

1. Completely remove the liquid gasket adhered to the timing chain case assembly, cylinder block and cylinder head, and then degrease using the volatile degreasing agent.

2. Remove all the sealant adhering to the gasket between the cylinder head and cylinder block (three-surface aligned part). Then, degrease the surfaces with the volatile degreasing agent.

3. As for the three-surface aligned part above, the engine oil oozes from the cylinder head gasket. Thus, quickly apply the sealant to it after degreasing.

Specified sealant: ThreeBond 1217G or equivalent

4. To the timing chain case assembly installation surface, apply the sealant without a gap. However, overlap the sealant at the "D" shown in the figure.

Specified sealant: ThreeBond 1217G or equivalent

NOTE: Install the timing chain case assembly immediately after applying sealant.

CAUTION

- If the sealant contacts any other part during installation of the timing chain case assembly, apply sealant again before installing the timing chain case assembly.

- After the installation, until a sufficient period of time (one hour or more) elapses, do not apply the oil or water to the sealant application area or start the engine.

5. Install the timing chain case assembly to the cylinder block and cylinder head so that the sealant does not contact other parts.

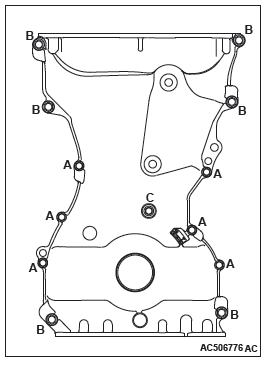

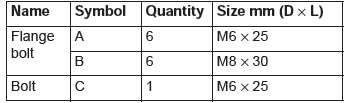

6. Insert the bolts to the timing chain case assembly as shown, and tighten them to the specified torque.

NOTE: D: Nominal diameter, L: Nominal length

Tightening torque:

A, C: 10 +- 2 N*m (89 +- 17 in-lb)

B: 24 +- 4 N*m (18 +- 2 ft-lb)

WATER PUMP PULLEY INSTALLATION

Temporarily tighten the water pump pulley mounting bolts.

Then, tighten them to the specified torque after the installation of drive belt.

Tightening torque: 9.0 +- 1.0 N*m (80 +- 9 in-lb)