Mitsubishi Outlander: DTC P0876, P0893, P0988, P1705, P1706, P1731, P1753, P1758, P1773, P1796, U0001, U0100, U0121, U0141

DTC P0876: High Clutch Pressure Switch System

DESCRIPTIONS OF MONITOR METHODS

- With the solenoid failure not detected and with 4th to 6th gear driving, the switch OFF status continues for 2 seconds. (The detection is achieved twice during 1 driving cycle*1, and it continues for 2 driving cycles.)

*1: Indicates the series of driving cycle "ignition key OFF → ON → drive → OFF". The "1 driving cycle", "2 driving cycle", and so on indicates how many cycles are required to detect a failure.

MONITOR EXECUTION

- 4th, 5th, and 6th gear driving

MONITOR EXECUTION CONDITIONS (OTHER MONITOR AND SENSOR)

Other Monitor (There is no temporary DTC stored in memory for the item monitored below)

- Not applicable

Sensor (The sensor below is determined to be normal)

- Not applicable

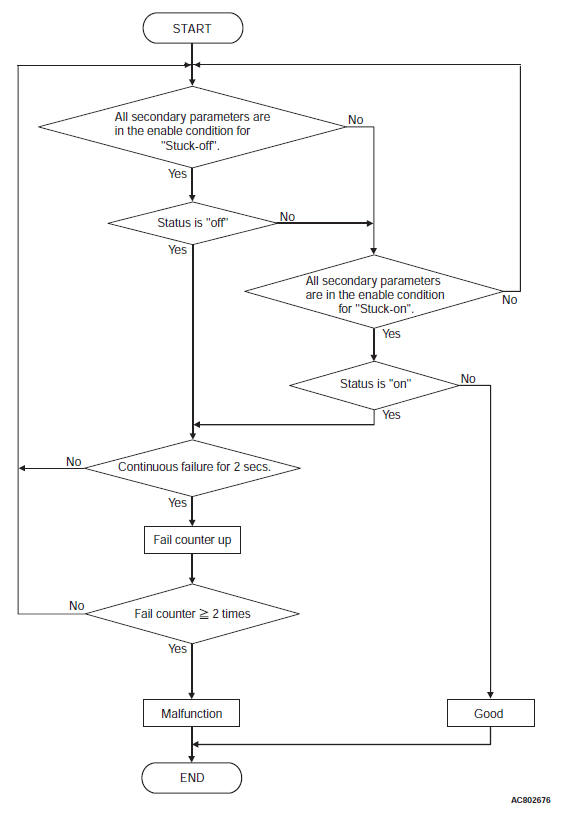

LOGIC FLOW CHARTS (Monitor Sequence)

DTC SET CONDITIONS

Check Conditions <Stuck-off>

- Transmission range switch position: D

- Gear position: 4th, 5th, 6th

- Time after shift changing finish: 2 seconds or more

Judgment Criteria <Stuck-off>

- High clutch pressure switch status: OFF (2 seconds × 2times)

Check Conditions <Stuck-on>

- Transmission range switch position: D or R

- Gear position: 1st, 2nd, 3rd, reverse

- Time after shift changing finish: 2 seconds or more

Judgment Criteria <Stuck-on>

- High clutch pressure switch status: ON (2 seconds × 2times)

OBD-II DRIVE CYCLE PATTERN

Drive in 4th, 5th, and 6th gears for 2 seconds or more.

TROUBLESHOOTING HINTS (THE MOST LIKELY CAUSES FOR THIS CODE TO BE SET ARE:)

- Malfunction of the high clutch pressure switch system circuit

- Damaged harness or connector

- Malfunction of the TCM

- Malfunction of the high clutch pressure switch system (valve body assembly)

- Malfunction of the valve body assembly, abnormal hydraulic circuit valve.

CAUTION For the incomplete gear shifting and slippage, first refer to the SYMPTOM CHART.

DIAGNOSIS

STEP 1. Check the DTC.

Q: Is the DTC other than the pressure switch set? (Is the code other than P0846, P0876, and P0988 set?)

YES : Check and repair the relevant DTC system.

NO : Go to Step 2.

STEP 2. Check the TCM terminal voltage.

[C-37 TCM connector (vehicle side, connected) ]

Measure the voltage between C-37 terminal No. 45 and body ground.

- High clutch engaged: 0 V

- Other than above: Battery positive voltage

Q: Is the check result normal?

YES : Go to Step 3.

NO : Go to Step 7.

STEP 3. Check between the TCM connector and A/T control solenoid valve assembly.

Check for continuity between C-37 TCM connector and B-111 A/T control solenoid valve assembly connector.

NOTE: Prior to the wiring harness inspection, check the intermediate connectors A-12 and repair that if necessary.

- Between C-37 terminal No. 45 and B-111 terminal No. 5: Continuity exists.

When the continuity check result is OK, check that the wiring harness is not shorted to the body and other wiring harness.

Q: Is the check result normal?

YES : Go to Step 4.

NO : Repair or replace the failure section.

STEP 4. Check the TCM, A/T control solenoid valve assembly connector pin terminals, and the connection status.

Q: Is the check result normal?

YES : Go to Step 5.

NO : Repair or replace the failure section.

STEP 5. Check between the A/T control solenoid valve assembly connector and high clutch pressure switch.

Check for continuity between the B-111 A/T control solenoid valve assembly connector terminals and the high clutch pressure switch connector terminals.

- Between B-111 terminal No. 5 and high clutch pressure switch: Continuity exists.

When the continuity check result is OK, check that the wiring harness is not shorted to the body and other wiring harness.

Q: Is the check result normal?

YES : Go to Step 6.

NO : Repair or replace the failure section.

STEP 6. Check the high clutch pressure switch body ground.

Check for continuity between the high clutch pressure switch body and ground.

- Between the high clutch pressure switch body and body ground: Continuity exists.

Q: Is the check result normal?

YES : Replace the valve body assembly, and then go to Step 8.

NO : Repair or replace the failure section.

STEP 7. Check the TCM, A/T control solenoid valve assembly connector pin terminals, and the connection status.

Q: Is the check result normal?

YES : Go to Step 9.

NO : Repair or replace the failure section.

STEP 8. Erase the DTC code, and drive the vehicle for a while.

Check that the normal code is displayed.

Q: Is the check result normal?

YES : The procedure is complete.

NO : Replace the TCM.

STEP 9. Erase the DTC code, and drive the vehicle for a while.

Check that the normal code is displayed.

Q: Is the check result normal?

YES : The procedure is complete.

NO : Return to START.

DTC P0893: Interlock Detection

DESCRIPTIONS OF MONITOR METHODS

When sudden deceleration (2.5 m/s2) exceeding the setting time is detected with combination as follows; Stoplight switch: correct, output shaft speed sensor: correct, hydraulic switch: incorrect.

MONITOR EXECUTION

- Continuous

MONITOR EXECUTION CONDITIONS (OTHER MONITOR AND SENSOR)

Other Monitor (There is no temporary DTC stored in memory for the item monitored below)

- Not applicable

Sensor (The sensor below is determined to be normal)

- Not applicable

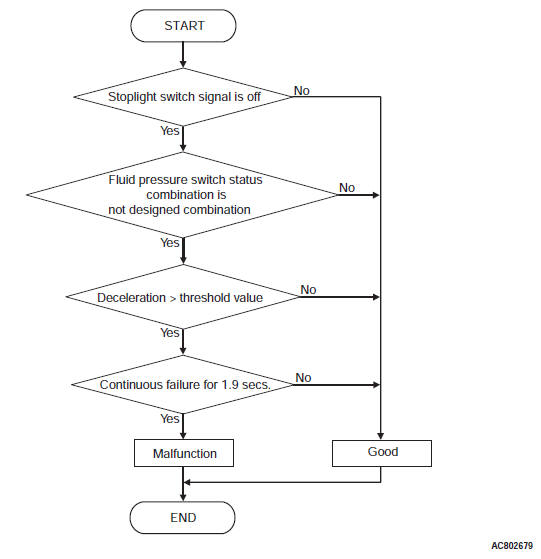

LOGIC FLOW CHARTS (Monitor Sequence)

DTC SET CONDITIONS

Check Conditions

- Fluid pressure switch status combination: not designed combination

- Stoplight switch signal: OFF.

Judgement Criteria

- Deceleration: more than threshold value. (1.9 second)

OBD-II DRIVE CYCLE PATTERN

Start the engine, drive at 60 km/h (37.3 mph) or more for 15 minutes in total.

TROUBLESHOOTING HINTS (THE MOST LIKELY CAUSES FOR THIS CODE TO BE SET ARE:)

- Malfunction of the P0720: output shaft speed sensor system circuit

- Damaged harness or connector

- Malfunction of the P0743: lock-up and low-reverse brake linear solenoid valve system circuit

- Malfunction of the P0753: low clutch linear solenoid valve system circuit

- Malfunction of the P0758: 2-6 brake linear solenoid valve system circuit

- Malfunction of the P0763: 3-5 reverse clutch linear solenoid valve system circuit

- Malfunction of the P0768: high clutch linear solenoid valve system circuit

- Malfunction of the P1753: low clutch shift solenoid valve system circuit

- Malfunction of the P1758: low-reverse brake shift solenoid valve system circuit

- Malfunction of the P0846: 2-6 brake pressure switch system circuit

- Malfunction of the P0876: high clutch pressure switch system circuit

- Malfunction of the P0988: low-reverse brake pressure switch system circuit

DIAGNOSIS

STEP 1. Check the DTC.

Check if the following DTCs are set.

- P0720 output shaft speed sensor

- P0743 lock-up and low-reverse brake linear solenoid valve

- P0753 low clutch linear solenoid valve

- P0758 2-6 brake linear solenoid valve

- P0763 3-5 reverse clutch linear solenoid valve

- P0768 high clutch linear solenoid valve

- P1753 low clutch shift solenoid valve

- P1758 low-reverse brake shift solenoid valve

- P0846 2-6 brake pressure switch

- P0876 high clutch pressure switch

- P0988 low-reverse brake pressure switch

Q: Is the check result normal?

YES : Go to Step 2.

NO : Repair or replace the failure section.

STEP 2. Check TCM related to the solenoid, pressure switch and output shaft speed sensor, the A/T control solenoid valve assembly connector pin terminals, and the connection status.

Q: Is the check result normal?

YES : Replace the TCM, and then go to Step 3.

NO : Repair or replace the failure section.

STEP 3. Erase the DTC code, and drive the vehicle for a while.

Check that the normal code is displayed.

Q: Is the check result normal?

YES : The procedure is complete.

NO : Replace the transaxle assembly.

DTC P0988: Low-Reverse Brake Pressure Switch System

DESCRIPTIONS OF MONITOR METHODS

- During reverse driving, the switch OFF status continues for 2 seconds. (The detection is achieved twice during 1 driving cycle*1, and it continues for 2 driving cycles.)

*1: Indicates the series of driving cycle "ignition key OFF → ON → drive → OFF". The "1 driving cycle", "2 driving cycle", and so on indicates how many cycles are required to detect a failure.

MONITOR EXECUTION

- Reverse gear driving

MONITOR EXECUTION CONDITIONS (OTHER MONITOR AND SENSOR)

Other Monitor (There is no temporary DTC stored in memory for the item monitored below)

- Not applicable

Sensor (The sensor below is determined to be normal)

- Not applicable

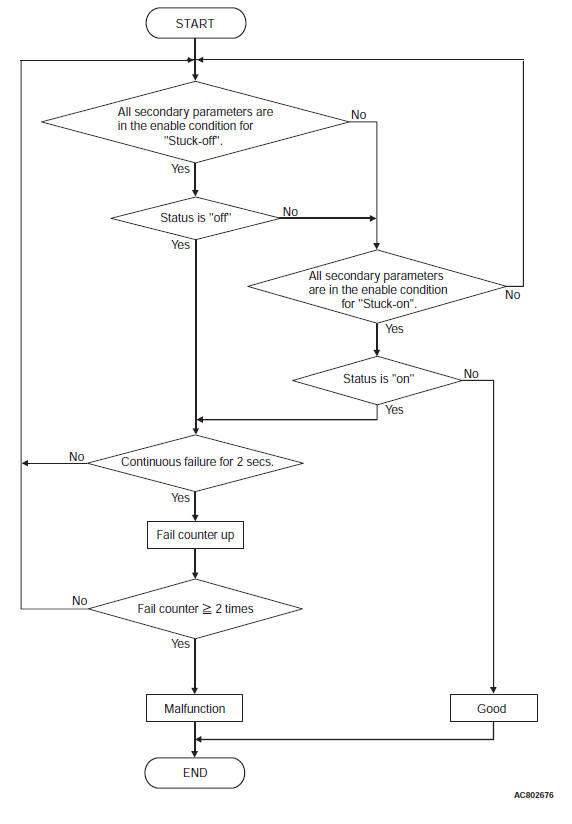

LOGIC FLOW CHARTS (Monitor Sequence)

DTC SET CONDITIONS

Check Conditions <Stuck-off>

- Transmission range switch position: R

- Gear position: reverse

- Time after shift changing finish: 2 seconds or more

Judgment Criteria <Stuck-off>

- Low-reverse brake pressure switch status: OFF (2 seconds × 2times)

Check Conditions <Stuck-on>

- Transmission range switch position: D

- Gear position: 1st, 2nd, 3rd, 4th, 5th, 6th

- Time after shift changing finish: 2 seconds or more

Judgment Criteria <Stuck-on>

- Low-reverse brake pressure switch status: ON (2 seconds × 2times)

OBD-II DRIVE CYCLE PATTERN

Reverse gear driving for 2 seconds or more

TROUBLESHOOTING HINTS (THE MOST LIKELY CAUSES FOR THIS CODE TO BE SET ARE:)

- Malfunction of the low-reverse brake pressure switch system circuit

- Damaged harness or connector

- Malfunction of the TCM

- Malfunction of the low-reverse brake pressure switch system (valve body assembly)

- Malfunction of the valve body assembly, abnormal hydraulic circuit valve.

CAUTION For the incomplete gear shifting and slippage, first refer to the SYMPTOM CHART.

DIAGNOSIS

STEP 1. Check the DTC.

Q: Is the DTC other than the pressure switch set? (Is the code other than P0846, P0876, and P0988 set?)

YES : Check and repair the relevant DTC system.

NO : Go to Step 2.

STEP 2. Check the TCM terminal voltage.

[C-37 TCM connector (vehicle side, connected) ]

Measure the voltage between C-37 terminal No. 43 and body ground.

- Low-reverse brake engaged: 0 V

- Other than above: Battery positive voltage

Q: Is the check result normal?

YES : Go to Step 3.

NO : Go to Step 7.

STEP 3. Check between the TCM connector and A/T control solenoid valve assembly.

Check for continuity between C-37 TCM connector and B-111 A/T control solenoid valve assembly connector.

NOTE: Prior to the wiring harness inspection, check the intermediate connectors A-12 and repair that if necessary.

- Between C-37 terminal No. 43 and B-111 terminal No. 7: Continuity exists.

When the continuity check result is OK, check that the wiring harness is not shorted to the body and other wiring harness.

Q: Is the check result normal?

YES : Go to Step 4.

NO : Repair or replace the failure section.

STEP 4. Check the TCM, A/T control solenoid valve assembly connector pin terminals, and the connection status.

Q: Is the check result normal?

YES : Go to Step 5.

NO : Repair or replace the failure section.

STEP 5. Check between the A/T control solenoid valve assembly connector and low-reverse brake pressure switch.

Check for continuity between the B-111 A/T control solenoid valve assembly connector terminals and the low-reverse brake pressure switch connector terminals.

- Between B-111 terminal No. 7 and low-reverse brake pressure switch: Continuity exists.

When the continuity check result is OK, check that the wiring harness is not shorted to the body and other wiring harness.

Q: Is the check result normal?

YES : Go to Step 6.

NO : Repair or replace the failure section.

STEP 6. Check the low-reverse brake pressure switch body ground.

Check for continuity between the low-reverse brake pressure switch body and ground.

- Between the low-reverse brake pressure switch body and body ground: Continuity exists.

Q: Is the check result normal?

YES : Replace the valve body assembly, and then go to Step 8.

NO : Repair or replace the failure section.

STEP 7. Check the TCM, A/T control solenoid valve assembly connector pin terminals, and the connection status.

Q: Is the check result normal?

YES : Go to Step 9.

NO : Repair or replace the failure section.

STEP 8. Erase the DTC code, and drive the vehicle for a while.

Check that the normal code is displayed.

Q: Is the check result normal?

YES : The procedure is complete.

NO : Replace the TCM.

STEP 9. Erase the DTC code, and drive the vehicle for a while.

Check that the normal code is displayed.

Q: Is the check result normal?

YES : The procedure is complete.

NO : Return to START.

DTC P1705: Throttle Position Sensor Information (Engine)

DESCRIPTIONS OF MONITOR METHODS

With the vehicle speed 5 km/h (3.1 mph) or more or the output shaft speed sensor normal, and after the A/T-ECU startup, when approximately 1 second has elapsed, if the TPS fail signal is received for 5 seconds, or the APS fail signal is received for 3 seconds from the engine ECU.

MONITOR EXECUTION

- Vehicle speed 5 km/h (3.1 mph) or more

MONITOR EXECUTION CONDITIONS (OTHER MONITOR AND SENSOR)

Other Monitor (There is no temporary DTC stored in memory for the item monitored below)

- Not applicable

Sensor (The sensor below is determined to be normal)

- Not applicable

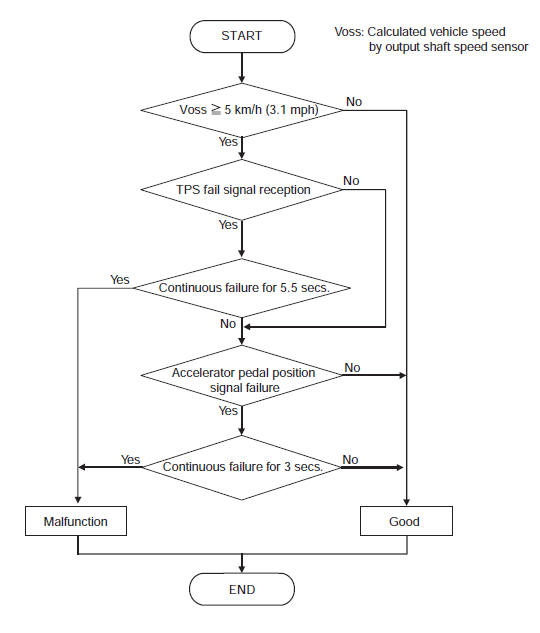

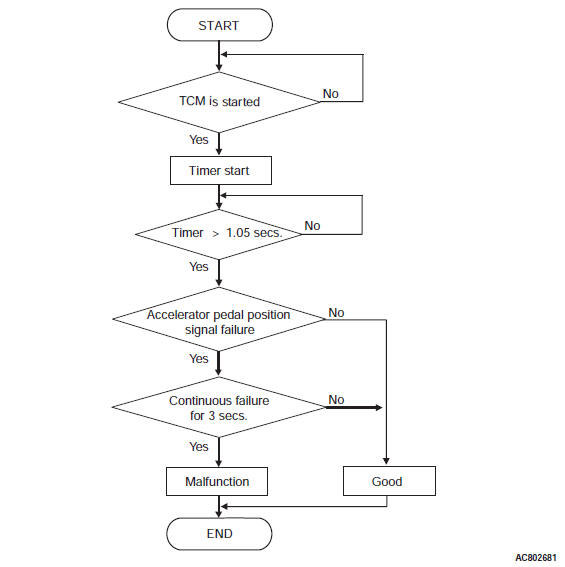

LOGIC FLOW CHARTS (Monitor Sequence)

DTC SET CONDITIONS

Check Conditions <Throttle position sensor>

- TCM is started: more than 1.05 seconds.

- Vehicle speed: 5 km/h(3.1 mph) or more.

Judgement Criteria <Throttle position sensor>

- Throttle position sensor signal: fail. (5.5 seconds)

Check Conditions <Accelerator pedal position sensor>

- TCM is started: more than 1.05 seconds.

Judgement Criteria <Accelerator pedal position sensor>

- Accelerator pedal position sensor signal: fail. (3 seconds)

OBD-II DRIVE CYCLE PATTERN

Drive with the vehicle speed 5 km/h (3.1 mph) or more for 5 seconds or more.

TROUBLESHOOTING HINTS (THE MOST LIKELY CAUSES FOR THIS CODE TO BE SET ARE:)

- Malfunction of the CAN

- Malfunction of the ECM

- Damaged harness or connector

- Malfunction of the throttle position sensor

- Malfunction of the TCM

DIAGNOSIS

STEP 1. Check for CAN communication system malfunction.

Q: Are the DTC U0001, U0100, U0141, P1705, P1706 set?

YES : Check and repair the CAN communication system.

NO : Go to Step 2.

STEP 2. Check the throttle position sensor and ECM-side main unit and connector wiring.

Q: Is the check result normal?

YES : Go to Step 3.

NO : Repair or replace the failure section.

STEP 3. Erase the DTC code, and drive the vehicle for a while.

Check that the normal code is displayed.

Q: Is the check result normal?

YES : The procedure is complete.

NO : Replace the TCM.

DTC P1706: Accelerator Pedal Position Information

DESCRIPTIONS OF MONITOR METHODS

- When approx. 1 second has elapsed after TCM started, the throttle pedal position signal seizure is detected for 3 seconds.

MONITOR EXECUTION

- Continuous

MONITOR EXECUTION CONDITIONS (OTHER MONITOR AND SENSOR)

Other Monitor (There is no temporary DTC stored in memory for the item monitored below)

- P0712: Malfunction of the transmission fluid temperature sensor (Short circuit)

- P0715: Malfunction of the Input shaft speed sensor system

Sensor (The sensor below is determined to be normal)

- Transmission fluid temperature sensor

- Input shaft speed sensor

LOGIC FLOW CHARTS (Monitor Sequence)

DTC SET CONDITIONS

Check Conditions

- TCM is started: more than 1.05 seconds.

Judgement Criteria

- Accelerator pedal position sensor signal: fail. (3 seconds)

OBD-II DRIVE CYCLE PATTERN

With the ignition switch ON, maintain the status for 10 seconds or more.

TROUBLESHOOTING HINTS (THE MOST LIKELY CAUSES FOR THIS CODE TO BE SET ARE:)

- Malfunction of the CAN

- Malfunction of the ECM

- Damaged harness or connector

- Malfunction of the throttle position sensor

DIAGNOSIS

STEP 1. Is the DTC code for ECM displayed?

Check that the failure related to the engine does not occur.

Q: Is the check result normal?

YES : Go to Step 2.

NO : Repair or replace the failure section.

STEP 2. Check the throttle position sensor and ECM-side main unit and connector wiring.

Q: Is the check result normal?

YES : Go to Step 3.

NO : Repair or replace the failure section.

STEP 3. Erase the DTC code, and drive the vehicle for a while.

Check that the normal code is displayed.

Q: Is the check result normal?

YES : The procedure is complete.

NO : Return to START.

DTC P1731: 1st Engine Brake Detection

DESCRIPTIONS OF MONITOR METHODS

- With the mode other than SPORT MODE and with the accelerator angle is smaller than 6/8, the correlation between the lock-up and low-reverse brake linear solenoid valve control current and the low-reverse brake pressure switch ON/OFF is abnormal.

TROUBLESHOOTING HINTS (THE MOST LIKELY CAUSES FOR THIS CODE TO BE SET ARE:)

- Transaxle assembly powertrain parts failure

- Malfunction of the valve assembly (Malfunction of hydraulic valve and hydraulic switch)

- Malfunction of the TCM

- Malfunction of the lock-up and low-reverse brake linear solenoid valve (valve assembly)

- Malfunction of the low-reverse brake pressure switch (valve assembly)

- Malfunction of the low clutch pressure switch (valve assembly)

- Malfunction of the low clutch linear solenoid valve (valve assembly)

- Malfunction of the low-reverse brake shift solenoid valve (valve assembly)

- Malfunction of the low clutch, low-reverse brake

DIAGNOSIS

STEP 1. Check the DTC.

Check that P0988 (Low-reverse brake pressure switch) is set.

Q: Is the DTC set? YES : Check and repair the relevant DTC system.

NO : Go to Step 2.

STEP 2. Check the DTC.

Check that the DTC other than P1731 (1st engine brake detection) is set.

Q: Is the DTC set?

YES : Check and repair the relevant DTC system.

NO : Go to Step 3.

STEP 3. Check the transmission fluid properties.

Check the status of the transmission fluid properties (smell, color, fouling).

- Black: A/T inside damage, seizure

- Milky: Water intrusion

Q: Is the check result normal?

YES : Go to Step 4.

NO : Remove the A/T from the vehicle, then check and repair the inside.

STEP 4. Check the transmission fluid level.

Q: Is the check result normal?

YES : Go to Step 5.

NO : Adjust the transmission fluid level, and then go to Step 5.

STEP 5. Check the wiring harness, connector, and sensor signal.

- Check the wiring harness and connectors of the low-clutch pressure switch and low-reverse brake pressure switch.

- Check the signals of C-37 TCM connector terminal No. 37 (output shaft speed sensor) and the terminal No. 38 (input shaft speed sensor).

Q: Is the check result normal?

YES : Go to Step 6.

NO : Repair or replace the failure section.

STEP 6. Hydraulic pressure test

Q: Is the check result normal?

YES : Go to Step 7.

NO : Remove the A/T from the vehicle, then check and repair the inside.

STEP 7. Erase the DTC code, and drive the vehicle for a while.

Check that the normal code is displayed.

Q: Is the check result normal?

YES : The procedure is complete.

NO : Return to START.

DTC P1753: Low Clutch Shift Solenoid Valve System

DESCRIPTIONS OF MONITOR METHODS

- During 1st to 4th driving, and with the lock-up function deactivated, an open circuit is detected for 200 milliseconds.

- During the 5th to 6th driving, and with the lock-up function deactivated, a short circuit is detected for 200 milliseconds.

MONITOR EXECUTION

- During with the lock-up deactivated

MONITOR EXECUTION CONDITIONS (OTHER MONITOR AND SENSOR)

Other Monitor (There is no temporary DTC stored in memory for the item monitored below)

- P0731: Malfunction of the 1st gear incorrect ratio

- P0732: Malfunction of the 2nd gear incorrect ratio

- P0733: Malfunction of the 3rd gear incorrect ratio

- P0734: Malfunction of the 4th gear incorrect ratio

- P0735: Malfunction of the 5th gear incorrect ratio

- P0729: Malfunction of the 6th gear incorrect ratio

Sensor (The sensor below is determined to be normal)

- Not applicable

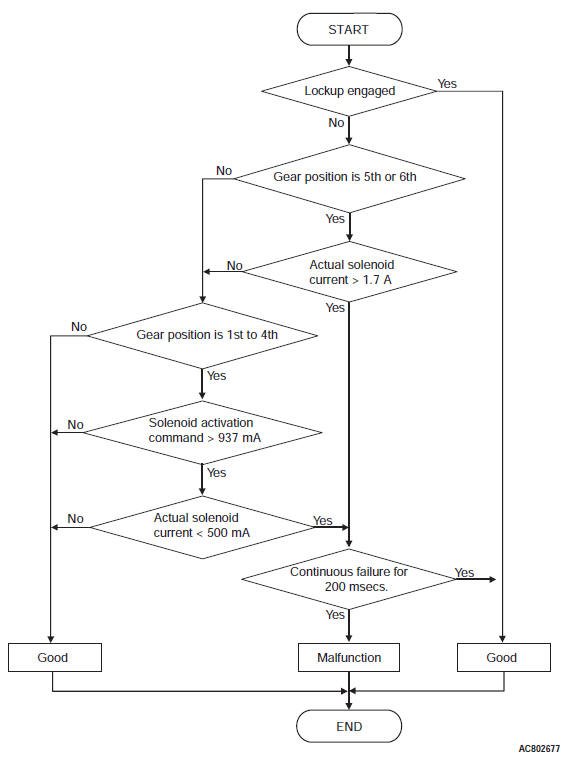

LOGIC FLOW CHARTS (Monitor Sequence)

DTC SET CONDITIONS

Check Conditions <Circuit continuity ground>

- Lock-up status: engaged.

- Gear position: 5th or 6th.

Judgment Criteria <Circuit continuity ground>

- Low clutch shift solenoid valve actual current: more than 1.7 A

Check Conditions <Circuit continuity open>

- Lock-up status: engaged.

- Gear position: 1st to 4th.

- Low clutch shift solenoid valve activation command: more than 937 mA

Judgment Criteria <Circuit continuity open>

- Low clutch shift solenoid valve actual current: less than 500 mA. (0.2 seconds)

OBD-II DRIVE CYCLE PATTERN

Drive at 55 km/h (34.2 mph) or less with the shift ranges of 1st, 2nd, 3rd, and 4th gear. Driving at 48 +- 2 km/h (29.8 +- 1.2 mph) with the 5th gear. Maintain each shift range for 1 second or more.

TROUBLESHOOTING HINTS (THE MOST LIKELY CAUSES FOR THIS CODE TO BE SET ARE:)

- Malfunction of the low clutch shift solenoid valve system circuit

- Damaged harness or connector

- Malfunction of the TCM

- Malfunction of the low clutch shift solenoid valve (valve body Assembly)

DIAGNOSIS

STEP 1. Check the TCM terminal voltage.

[C-38 TCM connector (vehicle side, connected) ]

Measure the voltage between terminal No. 14 and body ground.

- 5th and 6th: Battery positive voltage

- Other than above: 0 V

Q: Is the check result normal?

YES : Go to Step 5.

NO : Go to Step 2.

STEP 2. Check between the TCM connector and A/T control solenoid valve assembly connector.

Check for continuity between C-38 TCM connector and B-111 A/T control solenoid valve assembly connector.

NOTE: Prior to the wiring harness inspection, check the intermediate connectors A-12 and repair that if necessary.

- Between C-38 terminal No. 14 and B-111 terminal No. 22: Continuity exists.

When the continuity check result is OK, check that the wiring harness is not shorted to the body and other wiring harness.

Q: Is the check result normal?

YES : Go to Step 3.

NO : Repair or replace the failure section.

STEP 3. Check the low clutch shift solenoid.

Q: Is the check result normal?

YES : Go to Step 6.

NO : Go to Step 4.

STEP 4. Check between the A/T control solenoid valve assembly connector and the low clutch shift solenoid valve connector.

Check for continuity between the B-111 A/T control solenoid valve assembly connector terminals and the low clutch shift solenoid valve connector terminals.

- Between B-111 terminal No. 22 and low clutch shift solenoid valve: Continuity exists.

Q: Is the check result satisfactory?

YES : Replace the valve body assembly.

NO : Repair or replace the failure section.

STEP 5. Check the TCM and A/T control solenoid valve assembly connector pin terminals and the connection status.

Q: Is the check result normal?

YES : Go to Step 7.

NO : Repair or replace the failure section.

STEP 6. Check the TCM and A/T control solenoid valve assembly connector pin terminals and the connection status.

Q: Is the check result normal?

YES : Replace the TCM.

NO : Repair or replace the failure section.

STEP 7. Erase the DTC code, and drive the vehicle for a while.

Check that the normal code is displayed.

Q: Is the check result normal?

YES : The procedure is complete.

NO : Return to START.

DTC P1758: Low-Reverse Brake Shift Solenoid Valve System

DESCRIPTIONS OF MONITOR METHODS

- With the ignition switch ON, the open or short circuit is detected for 200 milliseconds.

MONITOR EXECUTION

- Continuous

MONITOR EXECUTION CONDITIONS (OTHER MONITOR AND SENSOR)

Other Monitor (There is no temporary DTC stored in memory for the item monitored below)

- P0731: Malfunction of the 1st gear incorrect ratio

- P0732: Malfunction of the 2nd gear incorrect ratio

- P0733: Malfunction of the 3rd gear incorrect ratio

- P0734: Malfunction of the 4th gear incorrect ratio

- P0735: Malfunction of the 5th gear incorrect ratio

- P0729: Malfunction of the 6th gear incorrect ratio

Sensor (The sensor below is determined to be normal)

- Not applicable

MONITOR EXECUTION CONDITIONS (OTHER MONITOR AND SENSOR)

Other Monitor (There is no temporary DTC stored in memory for the item monitored below)

- P0731: Malfunction of the 1st gear incorrect ratio

- P0732: Malfunction of the 2nd gear incorrect ratio

- P0733: Malfunction of the 3rd gear incorrect ratio

- P0734: Malfunction of the 4th gear incorrect ratio

- P0735: Malfunction of the 5th gear incorrect ratio

- P0729: Malfunction of the 6th gear incorrect ratio

Sensor (The sensor below is determined to be normal)

- Not applicable

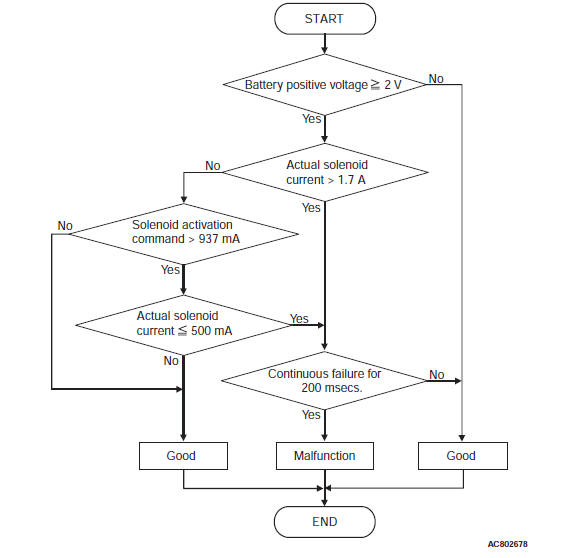

LOGIC FLOW CHARTS (Monitor Sequence)

DTC SET CONDITIONS

Check Conditions <Circuit continuity ground>

- Voltage of battery: 2 volts or more.

Judgment Criteria <Circuit continuity ground>

- Low-reverse brake shift solenoid valve actual current: more than 1.7 A (0.2 second)

Check Conditions <Circuit continuity open>

- Voltage of battery: 2 volts or more.

- Low-reverse brake shift solenoid valve activation command: more than 937 mA

Judgment Criteria <Circuit continuity open>

- Low-reverse brake shift solenoid valve actual current: less than 500 mA. (0.2 seconds)

OBD-II DRIVE CYCLE PATTERN

With the ignition switch ON, maintain the status for 10 seconds or more.

TROUBLESHOOTING HINTS (THE MOST LIKELY CAUSES FOR THIS CODE TO BE SET ARE:)

- Malfunction of the low-reverse brake shift solenoid valve system circuit

- Damaged harness or connector

- Malfunction of the TCM

- Malfunction of the low-reverse brake shift solenoid valve (valve body assembly)

DIAGNOSIS

STEP 1. Check the TCM terminal voltage.

[C-37 TCM connector (vehicle side, connected) ]

Measure the voltage between the terminal No. 51 and body ground.

- Reverse and 1st coast: Battery positive voltage

- Other than above: 0 V

Q: Is the check result normal?

YES : Go to Step 5.

NO : Go to Step 2.

STEP 2. Check between the TCM connector and A/T control solenoid valve assembly connector.

Check for continuity between C-37 TCM connector and B-111 A/T control solenoid valve assembly connector.

NOTE: Prior to the wiring harness inspection, check the intermediate connectors A-12 and repair that if necessary.

- Between C-37 terminal No. 51 and B-111 terminal No. 17: Continuity exists.

When the continuity check result is OK, check that the wiring harness is not shorted to the body and other wiring harness.

Q: Is the check result normal?

YES : Go to Step 3.

NO : Repair or replace the failure section.

STEP 3. Check the low-reverse brake shift solenoid.

Q: Is the check result normal?

YES : Go to Step 6.

NO : Go to Step 4.

STEP 4. Check between the A/T control solenoid valve assembly connector and the low-reverse brake shift solenoid valve connector.

Check for continuity between the B-111 A/T control solenoid valve assembly connector terminals and the low-reverse brake shift solenoid valve connector terminals.

- Between B-111 terminal No. 17 and low-reverse brake shift solenoid valve: Continuity exists.

Q: Is the check result satisfactory? YES : Replace the valve body assembly.

NO : Repair or replace the failure section.

STEP 5. Check the TCM and A/T control solenoid valve assembly connector pin terminals and the connection status.

Q: Is the check result normal?

YES : Go to Step 7.

NO : Repair or replace the failure section.

STEP 6. Check the TCM and A/T control solenoid valve assembly connector pin terminals and the connection status.

Q: Is the check result normal?

YES : Replace the TCM.

NO : Repair or replace the failure section.

STEP 7. Erase the DTC code, and drive the vehicle for a while.

Check that the normal code is displayed.

Q: Is the check result normal?

YES : The procedure is complete.

NO : Return to START.

DTC P1773: ABS Information (ABS/ASC)

DESCRIPTIONS OF MONITOR METHODS

- When approx. 1 second has elapsed after TCM started, the ABS/ASC abnormality signal is received via the CAN communication with vehicle speed at 55 km/h (34.4 mph) or more.

MONITOR EXECUTION

- Vehicle speed 55 km/h (34.4 mph) or more

MONITOR EXECUTION CONDITIONS (OTHER MONITOR AND SENSOR)

Other Monitor (There is no temporary DTC stored in memory for the item monitored below)

- Not applicable

Sensor (The sensor below is determined to be normal)

- Not applicable

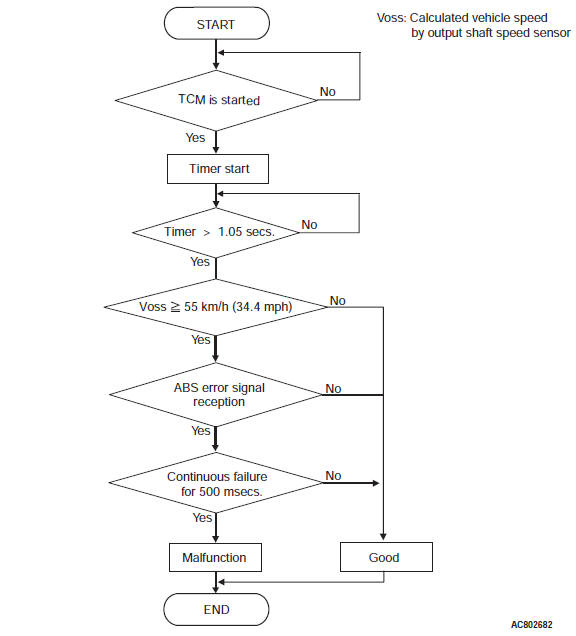

LOGIC FLOW CHARTS (Monitor Sequence)

DTC SET CONDITIONS

Check Conditions

- TCM is started: more than 1.05 seconds.

- Vehicle speed: more than 55 km/h (34.4 mph).

Judgement Criteria

- ABS status signal: fail. (0.5 second)

OBD-II DRIVE CYCLE PATTERN

Drive with the vehicle speed 5 km/h or more for 5 seconds or more.

TROUBLESHOOTING HINTS (THE MOST LIKELY CAUSES FOR THIS CODE TO BE SET ARE:)

- Malfunction of the CAN

- Malfunction of the ABS/ASC-ECU

DIAGNOSIS

STEP 1. Check the ABS/ASC-ECU.

Check if a failure related to ABS/ASC-ECU occurs.

Q: Is the check result satisfactory? YES : Go to Step 2.

NO : Repair or replace the failure section.

STEP 2. Check the ABS/ASC-ECU connector pin terminal and the connection status.

Q: Is the check result normal?

YES : Go to Step 3.

NO : Repair or replace the failure section.

STEP 3. Erase the DTC code, and drive the vehicle for a while.

Check that the normal code is displayed.

Q: Is the check result normal?

YES : The procedure is complete.

NO : Return to START.

Code No. P1796: Idle neutral control malfunction

DIAGNOSTIC TROUBLE CODE SET CONDITIONS

- With the idle neutral control, the status that the "actual slip speed − target slip speed" is faster than 300 r/min continues for 10 seconds.

- 1.05 seconds after the TCM activation, the failure signal of longitudinal G-sensor is received.

PROBABLE CAUSES

- Malfunction of the CAN circuit

- Malfunction of the P0753: low clutch linear solenoid valve system

- Malfunction of the P0731: 1st gear incorrect ratio

- Malfunction of the TCM

DIAGNOSTIC PROCEDURE

STEP 1. M.U.T.-III CAN bus diagnostics.

Use scan tool to perform the CAN bus diagnosis.

Q: Is the check result normal?

YES : Go to Step 2.

NO : Repair the CAN bus line.

STEP 2. Check the diagnostic trouble code.

Check the ASC diagnostic trouble code.

Q: Is the diagnostic trouble code set?

YES : Check and repair the relevant diagnostic trouble code system.

NO : Go to Step 3.

STEP 3. Perform the troubleshooting for diagnostic trouble code No. P0753: low clutch linear solenoid valve and diagnostic trouble code No. P0731: 1st gear incorrect ratio.

Check whether the diagnostic trouble code is reset.

Q: Is diagnostic trouble code No.P1796 set?

YES : Replace the TCM.

NO : This diagnosis is complete.

DTC U0001: Can Bus Off

DESCRIPTIONS OF MONITOR METHODS

- Open circuit or short circuit occurs in the CAN communication line (CAN_H, CAN_L).

- The communication becomes impossible with all the control modules for 0.5 seconds or more.

MONITOR EXECUTION

- Continuous

MONITOR EXECUTION CONDITIONS (OTHER MONITOR AND SENSOR)

Other Monitor (There is no temporary DTC stored in memory for the item monitored below)

- P0712: Malfunction of the transmission fluid temperature sensor (Short circuit)

- P0715: Malfunction of the Input shaft speed sensor system

- P0731: Malfunction of the 1st gear incorrect ratio

- P0732: Malfunction of the 2nd gear incorrect ratio

- P0733: Malfunction of the 3rd gear incorrect ratio

- P0734: Malfunction of the 4th gear incorrect ratio

- P0735: Malfunction of the 5th gear incorrect ratio

- P0729: Malfunction of the 6th gear incorrect ratio

- P0741: Malfunction of the Malfunction of the Torque converter clutch system (Stuck off)

- P0742: Malfunction of the Torque converter clutch system (Stuck on)

- P0846: Malfunction of the 2-6 brake pressure switch system

- P0876: Malfunction of the High clutch pressure switch system

- P0988: Malfunction of the Low-reverse brake pressure switch system

- P0893: Malfunction of the Interlock detection

- P1705: Malfunction of the Throttle position sensor information (engine)

- P1706: Malfunction of the Accelerator pedal position information

- P1773: Malfunction of the ABS information (ASC)

- U0100: Malfunction of the ECM time-out

Sensor (The sensor below is determined to be normal)

- Transmission fluid temperature sensor

- Input shaft speed sensor

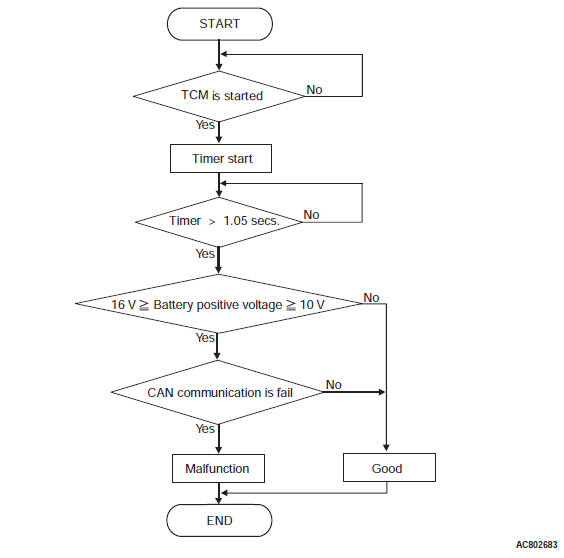

LOGIC FLOW CHARTS (Monitor Sequence)

DTC SET CONDITIONS

Check Conditions

- TCM is started: more than 1.05 seconds.

- A/T control relay voltage: 10 volts or more.

- A/T control relay voltage: 16 volts or less.

Judgement Criteria

- CAN communication: fail.

OBD-II DRIVE CYCLE PATTERN

- With the ignition switch ON, maintain the status for 10 seconds or more.

TROUBLESHOOTING HINTS (THE MOST LIKELY CAUSES FOR THIS CODE TO BE SET ARE:)

- Malfunction of the CAN circuit

- Malfunction of the TCM

- Damaged harness or connector

- Malfunction of the CAN system module

DIAGNOSIS

STEP 1. Check the CAN communication system malfunction.

- Check that the CAN system-related DTC code other than U0001 is set.

- Check that the CAN-related DTC is set with other relevant modules.

Q: Is the check result normal?

YES : Go to Step 2.

NO : Repair or replace the failure section.

STEP 2. Check the CAN communication lines.

[C-38 TCM connector (vehicle side, disconnected) ]

Between C-38 terminal No. 10, 11 and the CAN communication lines of other ECU: Continuity exists.

When the continuity check result is OK, check that the wiring harness is not shorted to the body and other wiring harness.

Also, check for a short circuit between the twisted pair cables.

Q: Is the check result normal?

YES : Go to Step 3.

NO : Repair or replace the failure section.

STEP 3. Check the relevant ECUs and the TCM connector pin terminal, and the connection status.

Q: Is the check result normal?

YES : Repair or replace the failure section.

NO : Replace the TCM.

DTC U0100: ECM Time-out

DESCRIPTIONS OF MONITOR METHODS

- Open circuit or short circuit occurs in the CAN communication line (CAN_H, CAN_L).

- Reception from ECM becomes impossible for 0.5 seconds or more.

MONITOR EXECUTION

- Continuous

MONITOR EXECUTION CONDITIONS (OTHER MONITOR AND SENSOR)

Other Monitor (There is no temporary DTC stored in memory for the item monitored below)

- P0712: Malfunction of the transmission fluid temperature sensor (Short circuit)

- P0715: Malfunction of the Input shaft speed sensor system

- P0731: Malfunction of the 1st gear incorrect ratio

- P0732: Malfunction of the 2nd gear incorrect ratio

- P0733: Malfunction of the 3rd gear incorrect ratio

- P0734: Malfunction of the 4th gear incorrect ratio

- P0735: Malfunction of the 5th gear incorrect ratio

- P0729: Malfunction of the 6th gear incorrect ratio

- P0741: Malfunction of the Malfunction of the Torque converter clutch system (Stuck off)

- P0742: Malfunction of the Torque converter clutch system (Stuck on)

- P0846: Malfunction of the 2-6 brake pressure switch system

- P0876: Malfunction of the High clutch pressure switch system

- P0988: Malfunction of the Low-reverse brake pressure switch system

- P1705: Malfunction of the Throttle position sensor information (engine)

- P1706: Malfunction of the Accelerator pedal position information

Sensor (The sensor below is determined to be normal)

- Transmission fluid temperature sensor

- Input shaft speed sensor

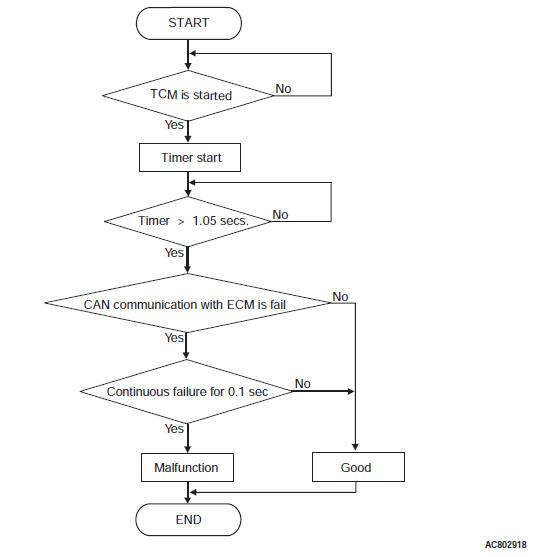

LOGIC FLOW CHARTS (Monitor Sequence)

DTC SET CONDITIONS

Check Conditions

- TCM is started: more than 1.05 seconds.

Judgement Criteria

- CAN communication with ECM: fail.

OBD-II DRIVE CYCLE PATTERN

With the ignition switch ON, maintain the status for 10 seconds or more.

TROUBLESHOOTING HINTS (THE MOST LIKELY CAUSES FOR THIS CODE TO BE SET ARE:)

- Damaged harness or connector

- Malfunction of the CAN communication

- Malfunction of the ECM

- Malfunction of the TCM

DIAGNOSIS

STEP 1. Check the CAN communication system malfunction.

- Check that the CAN system-related DTC code other than U0100 is set.

- Check if the CAN-related DTC is set with ECM.

- Check if the failure related to the engine occurs.

Q: Is the check result normal?

YES : Go to Step 2.

NO : Repair or replace the failure section.

STEP 2. Check the CAN communication lines.

[C-38 TCM connector (vehicle side, disconnected) ]

Between C-38 terminal No. 10, 11 and the CAN communication lines of ECM: Continuity exists.

When the continuity check result is OK, check that the wiring harness is not shorted to the body and other wiring harness.

Also, check for a short circuit between the twisted pair cables.

Q: Is the check result normal?

YES : Go to Step 3.

NO : Repair or replace the failure section.

STEP 3. Check ECM, the TCM connector pin terminal, and the connection status.

Q: Is the check result normal?

YES : Repair or replace the failure section.

NO : Replace the TCM.

DTC U0121: ABS/ASC-ECU Time Out

DESCRIPTIONS OF MONITOR METHODS

- Open circuit or short circuit occurs in the CAN communication line (CAN_H, CAN_L).

- Reception from ABS/ASC-ECU becomes impossible for 0.5 seconds or more.

TROUBLESHOOTING HINTS (THE MOST LIKELY CAUSES FOR THIS CODE TO BE SET ARE:)

- Damaged harness or connector

- Malfunction of the CAN communication

- Malfunction of the ABS/ASC-ECU

- Malfunction of the TCM

DIAGNOSIS

STEP 1. Check the CAN communication system malfunction.

- Check that the CAN system-related DTC code other than U0121 is set.

- Check if the CAN-related DTC is set with ABS/ASC-ECU.

- Check if the failure related to the ABS/ASC occurs.

Q: Is the check result normal?

YES : Go to Step 2.

NO : Repair or replace the failure section.

STEP 2. Check the CAN communication lines.

[C-38 TCM connector (vehicle side, disconnected) ]

Between C-38 terminal No. 10, 11 and the CAN communication lines of ABS/ASC-ECU: Continuity exists.

When the continuity check result is OK, check that the wiring harness is not shorted to the body and other wiring harness.

Also, check for a short circuit between the twisted pair cables.

Q: Is the check result normal?

YES : Go to Step 3.

NO : Repair or replace the failure section.

STEP 3. Check the ABS/ASC-ECU, the TCM connector pin terminal, and the connection status.

Q: Is the check result normal?

YES : Repair or replace the failure section.

NO : Replace the TCM.

DTC U0141: ETACS-ECU Time Out

DESCRIPTIONS OF MONITOR METHODS

- Open circuit or short circuit occurs in the CAN communication line (CAN_H, CAN_L).

- Reception from ETACS-ECU becomes impossible for 0.5 seconds or more.

TROUBLESHOOTING HINTS (THE MOST LIKELY CAUSES FOR THIS CODE TO BE SET ARE:)

- Damaged harness or connector

- Malfunction of the CAN communication

- Malfunction of the ETACS-ECU

- Malfunction of the TCM

DIAGNOSIS

STEP 1. Check the CAN communication system malfunction.

- Check that the CAN system-related DTC code other than U0141 is set.

- Check if the CAN-related DTC is set with ETACS-ECU.

- Check if the failure related to the ETACS occurs.

Q: Is the check result normal?

YES : Go to Step 2.

NO : Repair or replace the failure section.

STEP 2. Check the CAN communication lines.

[C-38 TCM connector (vehicle side, disconnected) ]

Between C-38 terminal No. 10, 11 and the CAN communication lines of ETACS-ECU: Continuity exists.

When the continuity check result is OK, check that the wiring harness is not shorted to the body and other wiring harness.

Also, check for a short circuit between the twisted pair cables.

Q: Is the check result normal?

YES : Go to Step 3.

NO : Repair or replace the failure section.

STEP 3. Check the ETACS-ECU, the TCM connector pin terminal, and the connection status.

Q: Is the check result normal?

YES : Repair or replace the failure section.

NO : Replace the TCM.